X1Jet XR

The X1JET XR inkjet printer is a stand-alone printing system that uses an XR Class piezo printhead. The printhead, ink system, maintenance station, and control electronics are all housed in one compact all-in-one device. Three different versions are available for different applications: in the Compact version, the printhead is mounted for horizontal marking. The Vario version printhead may be rotated 90 degrees anti-clockwise for added flexibility. The printhead is connected to the ink system via a 1000mm long hose in the Top version, which provides greater flexibility.

The oil-based XR 980 ink is ideal for printing on both mildly absorbent and absorbent product surfaces. Its quick drying period makes it ideal for printing on painted folding boxes.

Markoprint X1JET XR

Inkjet system based on tried and tested piezo technology

-

-

-

- Print system based on proven XAAR Piezo technology

-

-

-

-

-

- Compact casing with integrated print head, ink system, cleaning station and control electronics

-

-

-

-

-

- Simple nozzle cleaning with integrated maintenance station

-

-

-

-

-

- 382 individually controllable nozzles

-

-

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

Inkjet Coding Overview BrochureInk Guide 2015

- Choose from a wide range of 203, 300 and 600 dpi print engines

- Capable of handling print speeds up to 16 ips

- Numerous I/O’s ease interfacing with external devices

- Monitor operation via a web browser

- Available with RFID capability

Touch-Screen Label Print Station

Weber’s Elo Touch-Screen Print Station provides a compact, simple solution to selecting various label formats and then printing them using Weber label printer-applicators or tabletop label printers in virtually any production environment.

The Print Station is a stand-alone computer that allows you to set-up a control station for your labelling system that features a user-friendly touch-screen for easy operation by your personnel.

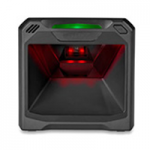

View ProductSymbol DS7708 Scanner

Easy to Deploy, High-Performance, “Can’t Miss” On-Counter Scanning

When it comes to on-counter scanning, the DS7708 scanner offers a feature set that puts it at the top of its class for performance, ease of use, easy deployment and total cost of ownership. With a large field of view that is over 50 percent larger than the competition, the DS7708 easily captures bar codes regardless of where they are located on an item. No matter what type of bar codes appear at the POS, the DS7708 can scan them all: 1D, 2D, printed and electronic.

View ProductAxicon 7025-S Barcode Verifier

The Axicon 7025-S verifier is designed for all barcodes where an 8, 10 or 20mil aperture is mandatory (such as GS1-128 and ITF-14), up to 195mm width including quiet zones. The simple to use design reduces user error and eliminates product damage whilst providing the highest level of accuracy achievable for verification.

View ProductModel 5300 Series Electric Tamp-Blow Label Printer-Applicator

This Weber exclusive label print-apply system provides high-resolution printing and high-speed operation combined with the high-speed electric tamp-blow method of label application.