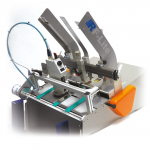

Tamper Evident Label Applicator

A core requirement of the European Directive 2011/62/EU that will come into force by 2016 is to equip the outer packaging of medicals with a tamper evident feature. Which should ensure the customer that he is the first opening the package.

Demands form different markets worldwide are showing the need for combined and integrated solutions to cover latest developments in industrial production and supply chain.

Counterfeiting is the illegal production and sale of goods, including packaging, bearing without authorization a trademark which is identical to a validly registered trademark or which cannot be distinguished from such a trademark.

Weber’s unique scope of supply are turn-key solutions including, but not limited to:

- Labelling Systems; in-line and off-line

- Coding / Inkjet Systems

- Barcode reading / verification

- Database Software Labels (verification and security labels)

- Full Service and installation supplies

A Track and Trace system is a mass serialization solution for pharmaceutical, cosmetics and food companies that prints a unique identifying code onto each product. By this, each individual product could be tracked throughout the whole supply chain, from production to the end consumer, and helps manufacturers significantly reduce counterfeiting by ensuring products can be easily identified.

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

Tamper_Evident_Weber_UK- High-performance printing

- 203 x 305 dpi

- Print width 4 and 6 inches

- Multi-language display

- Flexible connectivity

- Large memory

- Windows® – Compatible

- RFID Ready!

Geset Labelling Machine

Fast, reliable, economical solutions to product labelling: Geset 100, 300 and 700 labelling machines are part of a modular system. Up to 50 modules are available for design solutions to customer demands. The Geset 100 is a labelling machine for small production series, designed to produce small volumes as accurately and flexibly as would a large plant. Its robust construction renders it ideal both for intermittent use of only a few minutes per day and for multiple shift operation.

View ProductSato CL4e / CL6e Printer

FEATURES

RF-Lite

Low-cost offline coding system; ideal for companies looking to automate their date marking process for the first time.

View ProductZQ500 SERIES Mobile Printers

Extreme environments and bangs and bumps are no match for these lightweight, compact printers. Zebra’s ZQ510™ and ZQ520™ printers are the most rugged printers available. They perform in the widest operating temperature range in the industry and can withstand repeated drops to concrete from up to 6.6 feet. Water spray is no match with their IP54 rating. Featuring Zebra’s Link-OS® environment, these premium printers are easy to integrate, manage and maintain. With large buttons and a user-friendly interface, they are easy to operate, even when wearing gloves.

View Product