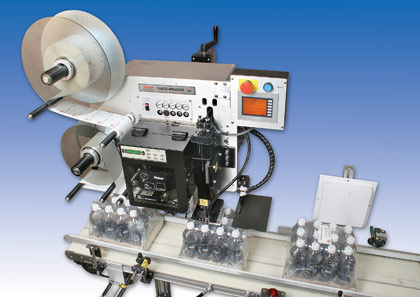

Model 5300 RFID Smart Label Printer-Applicator

Weber’s exclusive Model 5300 RFID label printer-applicator makes it easy to print, encode, verify and apply pressure-sensitive RFID smart labels to cartons and pallet loads in one automatic operation. In addition, the system determines if a tag is unverifiable and rejects it prior to application.

- Choose from 203 and 300 dpi print engines

- Capable of handling print speeds up to 16 ips

- Numerous I/O’s ease interfacing with external device

- Monitor operation via a web browser

Model 5300 RFID Label Printer-Applicator

Designed and engineered by Weber, this system provides high quality smart labelling that will meet the RFID supply chain requirements of major retailers and government agencies, and ensures precise label printing and application.

The Model 5300 RFID offers a selection of thermal/thermal-transfer print-encode engines that produce smart labels imprinted with text, bar codes and graphics at 203 or 300 dpi. Depending on the print engine selected, smart labels can be up to 5″ wide and 6″ long and can be dispensed at up to 16 ips.

As a smart label is printed, the Model 5300 RFID’s integrated encoder simultaneously transfers digital information to the thin, ultra-high frequency (UHF) transponder that is embedded in the pressure-sensitive label material.

That encoded information is instantly verified by the system, which then applies the smart label to the top or side of a carton or pallet load as it moves by on a conveyor line. Labels are applied using the non-contact, tamp-blow method, which gently blows the label onto the surface from 0.25″ and is accurate to within 0.06″.

The Model 5300 RFID also provides XML-enabled printing to permit direct smart label printing and encoding from leading ERP applications.

Pre-Apply Reject

If a tag is not verifiable, the system’s unique swing plate automatically is deployed to intercept the smart label prior to application. This method does not alter print engine operation, media handling or dispensing, yet collects and counts the rejected labels for subsequent disposition.

The print engines encode EPC Gen 2 protocols; and because its firmware is upgradeable to support new protocols, users are assured that they can seamlessly upgrade to future RFID protocols as needed.

In addition, Weber is offering special retrofit kits that will enable present users of Model 5300 printer-applicators to upgrade their units to meet the requirements of smart labelling without completely replacing existing systems.

Special Features & Options

The Model 5300 RFID system includes a number of noteworthy features that add to the operational versatility of this printer-applicator:

• Browser-based monitoring: The status of all operational functions and configurations can be monitored by logging on to a web page that is unique to each Model 5300 unit.

• Numerous I/O’s: The system can be interfaced with many types of external devices.

• One-to-one media consumption: Special label unwind and rewind dimensions are matched to the system’s ribbon supply to ensure they are consumed at the same rate, reducing downtime and eliminating partial changeovers.

• Print job storage: Multiple label printing formats can be stored in the system’s memory, making it easier for an operator to select a job directly from the applicator instead of downloading a computer file.

The Model 5300 system boasts numerous additional features as well, including a microprocessor controller with downloadable firewall capability, various inputs/outputs, plus durable construction that will withstand harsh industrial environments.

Other options include a 15-foot umbilical connection that enables the remote location of the unit’s controller, an adjustable stand for optimum system orientation, label-on-pad sensor for added functionality plus beacon light alerts to signal the status of label and ribbon supplies.

Labels are formatted using Weber’s proprietary Legitronic® Labelling Software, a package that combines label design, editing and printing with RFID encoding to create great-looking, readable smart labels.

Pressure-sensitive smart labels embedded with EPC Gen 2 inlays are available from Weber. These labels are ideal for high-quality thermal/thermal-transfer imprinting. Weber also supplies a variety of compatible thermal-transfer ribbons.

Options

• Adjustable stand

• Label-on-pad sensor

• Product presence sensor

• RFID retrofit kits

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

X2Jet Touch

The particularly compact and cost-effective X2JET Plus System is ideal for the foodstuffs, chemicals, building materials, and pharmaceutical industries. This innovative system marks absorbent and semi-absorbent surfaces – fast, accurately and reliably. The touchscreen interface and animated graphics makes it user-friendly and easy-to-use. Using a USB stick, data transfer is simple and reliable.

View ProductZebra KR203 Kiosk Receipt Printer

An affordable, host-based kiosk printer for 3-inch-wide receipts, Zebra’s compact KR203™ printer delivers unparalleled value and reliability for a variety of self-service applications. The KR203 draws upon the kiosk PC’s processing power and memory resources instead of its own, making it a highly cost-effective choice for customers who need a high-quality kiosk printer at the lowest total cost of ownership.

View ProductZebra CS3000 Series Scanner

The innovative Zebra CS3000 Series enables enterprises to easily implement 1D laser scanning where either mobility or the cost and

size of a traditional scanning device is an inhibitor. Two models provide the flexibility for use in many applications. The CS3000 can be utilized in standalone mode for the batch scanning of bar codes, while the CS3070 offers batch mode as well as real-time bar code data transmission to a host application via a wireless Bluetooth® connection to smartphones, laptops and more. The result is a new level of affordability for 1D scanning — and the ability to streamline, error proof and simplify many business processes.

Axicon 12000 2D Barcode Verifier

The Axicon 12000 2D verifier is designed to give repeatably highly accurate results when verifying Datamatrix and similar barcodes. The Axicon 12000 conforms to all of the latest ISO, GS1 and Pharmaceutical standards – and the Axicon 12000 has pioneered the AI content checking for the different pharmaceutical requirements (CIP, Turkish Ministry of Health, etc). The Axicon 12000 is designed for all 2D barcodes where an aperture size of 3mil or more is required (up to the scan area available – see scan area details overleaf) – the user can set the aperture either directly or by specifying a required Application Standard.

View Product