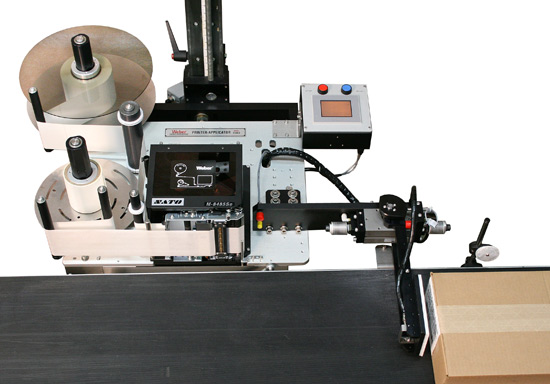

Model 5300 Series Swing-Tamp Label Printer-Applicator

This Weber exclusive provides high-resolution printing and high-speed operation combined with the swing-tamp method of label application that affixes labels to the leading or trailing side of a product.

- Choose from a wide range of 203, 300 and 600 dpi print engines

- Capable of handling print speeds up to 16 ips

- Numerous I/O’s ease interfacing with external devices

- Monitor operation via a web browser

- Available with RFID capability

Model 5300 Series Swing Tamp Label Printer-Applicator

Weber’s Model 5300 swing-tamp system is redefining the meaning of versatility in the printing and application of pressure-sensitive labels to the leading or trailing side of a product. This is the best way to add a label to your product front or back while moving along your production line.

In addition to offering a broad selection of high-quality print engines that feature various print resolutions and label dispensing rates, this Model 5300 system is available with optional RFID print-encode engines.

Standard direct and thermal-transfer print engines from manufacturers Zebra, SATO and Datamax produce text, bar codes and graphic images at 203, 300 or 600 dpi. The Zebra-based RFID models combine these printing capabilities with the encoding and verification of RFID inlays to meet EPC Gen 2 protocols.

Special Features & Options

The Model 5300 swing tamp system includes a number of noteworthy features that add to the operational versatility of this printer-applicator.

The Model 5300 swing tamp system includes a number of noteworthy features that add to the operational versatility of this printer-applicator.

• Swing tamp application: This method of label placement is used to apply a label to the front or back of a product as it travels on a conveyor line. A printed label is fed onto a pad and held by vacuum; the unit’s 90-degree swing arm then extends to apply the label.

• Browser-based monitoring: The status of all operational functions and configurations can be monitored by logging on to a web page that is unique to each Model 5300 unit.

• Numerous I/O’s: The system can be interfaced with many types of external devices.

• One-to-one media consumption: Special label unwind and rewind dimensions are matched to the system’s ribbon supply to ensure they are consumed at the same rate, reducing downtime and eliminating partial changeovers.

• Print job storage: Multiple label printing formats can be stored in the system’s memory, making it easier for an operator to select a job directly from the applicator instead of downloading a computer file.

The Model 5300 swing tamp system boasts numerous additional features including an upgradeable microprocessor controller, various inputs/outputs, plus durable construction that will withstand harsh industrial environments.

There also are several optional enhancements that can increase the system’s functionality. A product height sensor, for example, enables the printer-applicator to label items of varying heights delivered by the same conveyor.

Other options include a 15-foot umbilical connection that enables the remote location of the unit’s controller; an adjustable stand for optimum system orientation; label-on-pad and product-presence sensors; plus beacon light alerts to signal the status of label and ribbon supplies.

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

5300- High-performance printing

- 203 x 305 dpi

- Print width 4 and 6 inches

- Multi-language display

- Flexible connectivity

- Large memory

- Windows® – Compatible

- RFID Ready!

Zebra ZD410

The ZD410 is the smallest printer in its class, fitting easily in the most space-constrained desktop or shelf. Available with either 203 dpi or 300 dpi print resolution, the ZD410 is ideal for printing labels with a shelf life of less than one year. The ZD410 is currently available for purchase only in North America and the European Union countries. It will be launched in other countries throughout 2016.

View ProductZebra FS70 Fixed Industrial Scanner

Today more than ever, the increasing demands of international commerce and its global supply chain are pressuring companies to deliver more — and to do it faster. From manufacturing to logistics to the end customer, success is driven by the ability to quickly move and track the products that drive your business.

The FS70 Fixed Industrial Scanner is your configurable and customisable solution. Easily keep pace with your business, enabling quality control and track-and-trace of every part and package as it moves through production, storage and fulfilment. Whether you need a high-powered lens to read a very small barcode from a long distance, or a wide-angle lens to capture barcodes on extremely large parts, the FS70 addresses it all. C-mount external lenses allow you to achieve the working range and field of view your application and environment requires. And compatibility with virtually any external lighting solution ensures reading of the most challenging barcodes — even low-contrast direct part marks or those printed on curved or reflective surfaces. The result? Best-in-class production, warehousing, distribution and logistics processes that inspire your business to reach its highest potential.

View Product

Sato CL4e / CL6e Printer

FEATURES

X1Jet HP Stitch MK2

The Markoprint X1JET Stitch is a self-contained inkjet printing system that uses tried-and-true HP Class printing technology. Its space-saving electronics are hidden behind the cartridge, allowing it to be installed in confined areas. This entry system is especially useful for printing many 12.5 mm print pictures at the same time, which is typical in multi-lane deep-drawn packaging plants. To print a larger print image (up to 100 mm) , up to 8 X1JET Stitch printheads can be cascaded . The patented Click’n’Print cartridge holder makes replacing cartridges a breeze at any time. The SmartCard function of the system detects the ink cartridge and automatically sets all parameters.

View Product