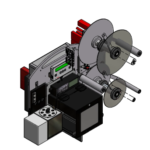

Geset 117 Top and Bottom Labelling System

The Geset 117 labelling system is used to label square products on the top and bottom side automatically. Depending on the type and dimension of the product, different label sizes are used. The products are fed manually or by a conveying system provided by the customer at an infeed passage on the labelling system. Care should be taken on accurate alignment of the products. It is essential that the products are forwarded separately to the applicator with a gap between each other.

When the light barrier is reached, an application trigger is tripped. Both label applicators apply then in Wipe On procedure a label onto the product. The label on top side is pushed on the product by a brush or roller. The label on bottom side is pushed on the product by the self-weight of the product. After labelling the products move on and can be removed from conveyor by the customer.

-

-

- Labelling at top-and bottom side of square products

- System on rolls and rubber feet

- Robust aluminium frame

- Simple unmistakable operation by buttons

- Speed of base conveyor can be adjusted by frequency converter

- Proven and reliable applicator technique provided by Alpha Compact, 150mm label width

- Performances of up to 100 products per minute are possible

-

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

Geset 117 Instruction ManualGeset 117 Technical Information

Geset 117 Computer Assisted Design

Alpha Compact Pre-Printed Labelling System

Our Alpha Compact Range of Labelling Systems, Compact, Lightweight, Durable and Easy to Use.

View ProductPLUSMARK – Premium Wax

PLUSMARK is the high performance wax ribbon from Weber. It offers all

the benefits of a general purpose wax ribbon with an improved print durability

and a capability to print on synthetic label materials.

LABELS on the GO!

Summary

LABELS on the GO! provides you with the ability to print labels from a database of information, which resides on a Mobile Device, then prints to a Mobile Label Printer. Flexible configuration allows the user to design custom label formats that can include linear or two dimensional bar codes. Also defined by the user is a database of multiple data elements to drive label printing. Use LABELS on the GO! when labels are needed and you do not have access to your host system or when you need to print new labels that are not currently available from your application software.

View ProductWeber LA4050BB – Blow Box High Speed Printer Applicator

Weber’s LA4050B Series Electric Labelling Print and Apply automated labeling systems feature industry-leading smart technology that use sensors to reduce label application complications, ensuring a one-to-one label-product match. As the leading all-electric Label Printer/Applicator manufacturer on the market, our pressure sensitive labeling systems enable customers to completely replace conventional pneumatic systems with semi-electric and or a fully electric option that controls the label with pinpoint accuracy in side, top, bottom and corner-wrap applications throughout the packaging process.

View Product