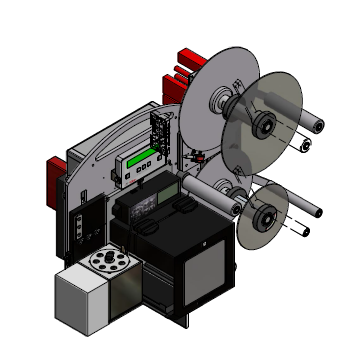

Weber LA4050BB – Blow Box High Speed Printer Applicator

Weber’s LA4050B Series Electric Labelling Print and Apply automated labeling systems feature industry-leading smart technology that use sensors to reduce label application complications, ensuring a one-to-one label-product match. As the leading all-electric Label Printer/Applicator manufacturer on the market, our pressure sensitive labeling systems enable customers to completely replace conventional pneumatic systems with semi-electric and or a fully electric option that controls the label with pinpoint accuracy in side, top, bottom and corner-wrap applications throughout the packaging process.

The Weber LA4050B BB (Blow Box) is an efficient High Speed Printing and Label Application System being a High throughput alternative to some traditional pneumatic Tamp Blow Labelling Systems. Traditionally used in High Speed Mailing Solutions the Blow Box System is capable of Printing and Application throughput in excess of 250 labels per minute. The LA4050B BB is predominantly used in the application of pressure sensitive labels on the top and sides of delicate or fragile substrates without making any contact unlike Direct Tamp Systems. The system is designed for use with a variety of Print Engines such as Sato, Zebra, Datamax etc. from 203dpi to 600dpi Printing Resolutions. Typically used for Top and Side Labelling the Weber LA4050B BB can be used in a variety of Industries from Logistics to Mailing and High Speed Packaging Systems.

Like all Weber Labelling Systems the unit is modular in design with easy to remove unwinder, rewinder, and Print Engine in the event of a critical component failure. This provides significant benefits for 24/7 operation where  downtime is a cost critical factor. The choice of Print Engines add to the versatility of the System and provides label size ranges from 50mm x 40mm to

downtime is a cost critical factor. The choice of Print Engines add to the versatility of the System and provides label size ranges from 50mm x 40mm to

100mm x 100mm at a speed of up to 250 labels per minute. The system has the same interface options (Alarm System, Error Control, Volt Free Output, M12 connection for Sensors etc.) as some of our other high end systems but with a low base cost. The all new Weber controller can manage the functions of the Labelling System with ease and simple to use touchscreen GUI.

The system has a pivoting U-Arm which allows rotation of the system by 360 degrees allowing the Labelling System to Print and Apply a label to any side of a product including Base Labelling of Products. The system can be mounted on its own individual stand, integrated directly into a packaging machine as part of an automated packaging line or mounted directly on one of our many handling systems providing a turn key solution to your particular Labelling requirements.

Other Benefits include:

- Low Total Cost of Ownership

- High accuracy Labelling

- Versatility and Flexibility in Labelling Configuration

- Easily adaptable to changes in Production

- Low Running Costs

- RFID Upgradeable

- High Throughput 24 / 7 Operation

- Available in 4″ wide and 6″ Wide Print Widths

- UK Service and Support Network

Additional Options include:

- Low label Warning System

- Protective Enclosure for Harsh Environments

- Barcode Scanning Module

- RFID Print Engine

- Vision System

- Choice of Product Detection Sensors

- Bespoke Handling Systems available

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

LPA_TIN_063D_LA_4050B_BB_GBZebra Symbol LS7808 Scanner

The advanced Symbol LS7808 horizontal slot scanner from Zebra delivers exceptionally high first-pass read rates for faster checkout times

— and better customer service. The Symbol LS7808 represents the latest development in our three decade leadership in designing bar code scanners and our pioneering work in horizontal slot scanner technologies. The omni-directional scan pattern reads the bar code regardless of orientation, eliminating the need to precisely align products to the scanner. Advanced software algorithms reconstruct poorly printed and damaged codes, further increasing performance and speeding customers through the point of sale.

Juice Labels

If you want your brand of drinks, cold-pressed juices, or other beverages to stand out from the crowded store shelf, you have to have a design that sets you apart from the competition. Color code each flavor using bright colors that reflect the taste of the product. We have some great ideas that can help you improve the appearance of your juice brand. Weber can also help you pick the right materials to stand up to the refrigerated environment and still look refreshing.

View ProductOMNII XT15 Mobile Computer

Building on the unique adaptability of the proven Zebra Omnii™ platform, the all-new Omnii XT15 Series raises the bar even higher to deliver the highest levels of ruggedness and functionality. With the open source business model — giving you the flexibility and freedom to adapt your device with exactly what you need — and certified IP67 and IP65 rating, the Omnii XT15 Series delivers reliable performance and unparalleled adaptability for the most demanding of environments and applications.

View ProductFlex-Matic Label Applicator

The Flex-Matic has been developed to accurately apply labels to a wide range of flat products including Bags, Envelopes, Pamphlets, PCB’s etc. up to a maximum thickness of 4mm. Constructed to the highest engineering standards and comes complete with a 2 year warranty against manufacturing defects and are fully compliant with all current safety standards.

View Product