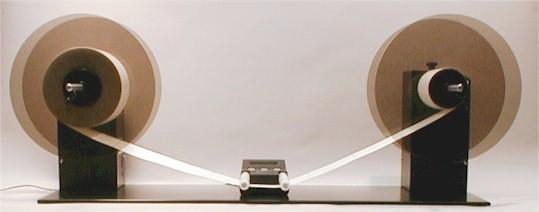

DRS – 2000 Desktop Rewind Station

IDEAL FOR PRODUCTION PREPARATION THE DRS-2000 DESKTOP REWIND STATION OFFERS:

- Off-line rewinding

- Counts both gap and reflective labels

- Variable Speed Control

- Tension Control

- Great for dispensers and hand held applicators.

- Excellent in visual inspection

- Easy to operate

- Rewind up to 61.5cm/sec.

Features:

- Wind Labels Roll To Roll

- Maximun Speed 61.5mm/sec

- Roll Width 2.5 cm to 23cm

- Auto Switching Power Supply 100-250 Volts 47-63 Hz

- Supports 30.5cm Rolls With 7.6cm Cores

- Winds Labels “In” to “Out” or “Out” to “In”

- Adjustable Speed Control

- Back Tension For Tight Uniform Rolls

- Splice Smaller Rolls Into One Large Roll

- The DRS 2000 comes with standard 7.6cm core holders.

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

DRS – 2000 DESKTOP REWIND STATIONZebra LS4208 – Handheld Scanner

LS4208 handheld laser bar code scanner, you’re able to effortlessly speed throughput, even with bar codes in poor condition. Wherever you need to quickly capture and process data — such as at the retail checkout counter, in pharmacies and hospitals, and in light warehouse environments — this ergonomically designed scanner helps you increase accuracy, improve productivity, cut maintenance

costs and reduce the risk of downtime.

Symbol DS7708 Scanner

Easy to Deploy, High-Performance, “Can’t Miss” On-Counter Scanning

When it comes to on-counter scanning, the DS7708 scanner offers a feature set that puts it at the top of its class for performance, ease of use, easy deployment and total cost of ownership. With a large field of view that is over 50 percent larger than the competition, the DS7708 easily captures bar codes regardless of where they are located on an item. No matter what type of bar codes appear at the POS, the DS7708 can scan them all: 1D, 2D, printed and electronic.

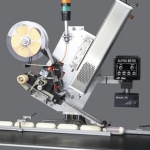

View ProductLaser Applicator: Alpha-Laser Label Applicator

The laser labeling solution comprises an Alpha label dispenser and a Solaris CO2 laser. The Alpha-Laser writes variable additional information such as best before dates, graphics or logistics data on pre-printed labels immediately before application.

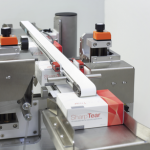

View ProductTamper Evident Label Applicator

A core requirement of the European Directive 2011/62/EU that will come into force by 2016 is to equip the outer packaging of medicals with a tamper evident feature. Which should ensure the customer that he is the first opening the package.

View Product