Barcode printer for your individual business needs

Desktop printers are versatile and can be used in barcode applications for example. Their size means they can be used whatever the time and place. The desktop printer is ready when- and wherever a label is required.

Our range of desktop printers offers you the best-possible solution in terms of resolution, label width, interface, label quantity and available options, such as blades or RFID capability. An interface handles printing of labels individually, e.g. with lot numbers from in-line production, an EAN code or barcode.

Weber Ireland offers you a range of barcode printers including solutions for labelling and printing control systems. Barcodes have been used successfully in many industries since the 1970s and can be printed on packaging or directly on the products themselves, simplifying ordering, storing and stocktaking for various businesses.

Representing data about an item or article, barcodes are printed using optical codes that are readable by a special bar code reader, scanner or interpretive software on computers, smartphones and other data processing devices. Weber Marking Systems provides barcode printer solutions for every requirement: bar code label printers for logistic units, quality assurance systems or for industrial processes. Additionally we supply different input units and software variants for barcode printing as well as technical support and services.

Barcode printers for labelling

Barcodes are used in many logistic processes such as ordering, delivery, transportation for tracking goods and controlling the commodity flow. An easy and simplified format is using labels that are stuck on the wrapper of goods or on other packaging units. Weber Marking Systems offers barcode label printers and dispensers for a fully automatic labelling process – practical for products, packaging, trays or pallets.

Our printers and dispensers of the LEGI-AIR series are designed for label formats in a range from 10 x 50 mm to 180 x 500 mm. They can work up to 240 labels per minute whilst working with domed surfaces. The systems have a modular design to fit into different industrial environments. Each LEGI-AIR barcode printer is ready to be modified for your own customised labelling system and will adjust to particular features, e.g. line speed, label size or content.

Services for inkjet barcode printer systems

In addition to barcode printers and label dispensers, Weber Ireland provides more than 1000 different label types as well as a wide variety of inks for diverse systems. You have the choice between quick-drying or water-soluble inks or pigmented properties.

As a central control system Markoprint is able to serve three different printhead technologies: small-format coding in high-resolution by Hewlett Packard, large-format coding by Trident and Lexmark industrial printheads. Weber is also an official partner of Zebra, a leading manufacturer of barcode printers. Please ask for our advice and service offers on Zebra printing.

Barcode printer with thermal transfer technology

Industrial barcode printers commonly apply thermal transfer technology. These printers use unique ribbons of color foil with wax, resin or a mixture of both. High temperature printheads transfer the colour to the label or have it fixed on different materials such as wood. Special foils even make it possible to print on metal, plastic and ceramic. Weber Marking Systems offers thermal transfer foils in 30 different qualities and optional widths and length for orders of 50 or more rolls. A barcode printer with thermo transfer technology can achieve the best and most durable printing qualities, perfectly made for barcodes and variable data.

Weber Marking System provides technical equipment for different barcode printer systems: coders for thermal or piezoelectric inkjets, and control systems by Markoprint with standard or windows-bases user interface. With so much diversity, we have everything you need for label design and barcode printing in high quality at Weber-marking.com.

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

Overview of the labelling products- High Speed Throughput 203 / 305 dpi

- Flexible Connectivity

- User friendly operation

- Low Cost of Ownership

- Unicode Support

- Built in Emulation Language

-

-

- Applies label up to 6″ high x 12″ long

-

-

-

- Handles up to 45 products/minute

-

-

-

- Placement accuracy of 0.03″

-

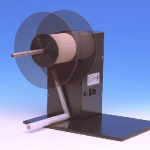

- Auto-switching Universal Power Supply for immediate adaptability anywhere in the world

- Compatible with all Direct Thermal and Thermal Transfer printers

- Electronic Speed Control will automatically synchronise winding speed to the speed of your printer

- Provides passive winding without skewing print or barcodes on your labels

- Rewind up to 61cm per second

- Easily handles labels up to 23cm wide

- Wind labels face in or face out

Vitamin Labels

An eye-catching label plus important info. If you have ever looked down the vitamin aisle at your local store, you can see that the different products are branded by color and label design. People need to trust their vitamin and supplement supplier so your label needs to reflect quality as well as contain the important information needed to use the product safely and effectively.

View ProductSato GZ4e Printer

Features

Weber 114 One-Sided/Two-Sided Labelling System

The brand-new Weber 114 system provides a simple, cost-effective solution to low volume labelling for applying labels to one or two sides of a straight-walled product or package. The Model 114 can be added to in-place production lines or operated manually as a stand-alone applicator.

The Weber 114 is easy to use and can be set-up quickly. During application, labels are peeled away from the liner and securely attached to products using the wipe-on label applicators.

The unit boasts robust steel construction making it perfect for lower-volume, intermittent labelling projects or multiple-shift larger-scale operations. This is a very reliable wipe-on application system that is built to last.

View Product

Electric Rewinder Models GLU-100 & Model GLR-100