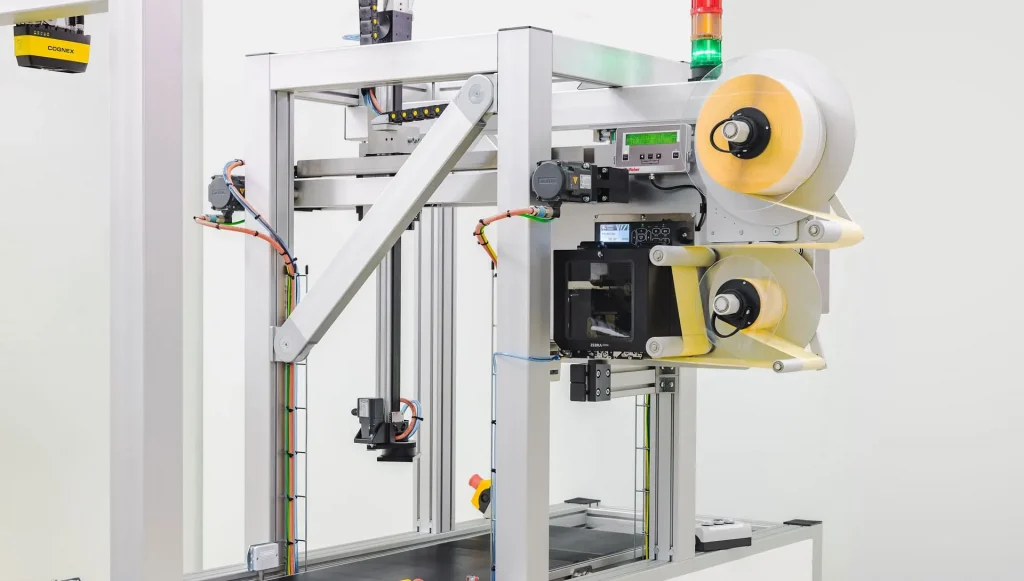

Weber Legi-Flex 6100 Label Print & Apply

With unprecedented demand on supply chain, the impact on companies warehouse and logistics processes are greater than ever. The need for automation is something that all businesses need to consider. The all new Weber Legi-Flex 6100 is a revolutionary new design that addresses the automation needs of businesses particularly in relation to the handling and labelling of products.

The Legi-Flex 6100 builds on the proven labelling technology of our LA4050 series but with a new “3D Label Application Module”. Traditionally, labelling systems label products in a fixed position as they are transported on a conveyor belt and requires alignment or product positioning guidance. The Legi-Flex 6100’s ground-breaking sensor technology recognises the position of each box and automatically adjusts itself to label the product in the correct position with pinpoint accuracy.

The Legi-Flex 6100 can automatically print and apply labels to a wide variety of packages and containers of varying shapes and sizes, and similar to all Weber Labelling Systems, is easy to integrate into existing packaging lines or as a standalone solution. What is most notable feature of the Legi-Air Flex 6100 is the “3D Labelling Module” . This means the Legi-Flex 6100 can support only one single Labelling System per line unlike traditional labelling systems that require additional labelling systems for each labelling position.

Key features:

-

- Minimal Downtime for Label Reel Replacement or Servicing

-

- Wide Variety of Label shapes and sizes catered for including, non batched products

-

- Innovative “3D Labelling System” concept

-

- Designed and built by Weber Packaging Solutions

-

- Enhanced Connectivity – Onboard IOT

-

- Choice of Print Engines to suit your existing configuration

-

- Modular Design – Rewind, Unwind, Applicator, Print Engine

-

- Full Range of 24/7 Remote or Onsite Support Services

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

Weber LA4050BB – Blow Box High Speed Printer Applicator

Weber’s LA4050B Series Electric Labelling Print and Apply automated labeling systems feature industry-leading smart technology that use sensors to reduce label application complications, ensuring a one-to-one label-product match. As the leading all-electric Label Printer/Applicator manufacturer on the market, our pressure sensitive labeling systems enable customers to completely replace conventional pneumatic systems with semi-electric and or a fully electric option that controls the label with pinpoint accuracy in side, top, bottom and corner-wrap applications throughout the packaging process.

View ProductLegi-Air 5300 Tyre Label Printer-Applicator

Fulfilling EU Guidelines

According to an EU regulation all new tyres produced in or after January 2012 and placed on the market within the EU must bear a standardized EU label, such as those already seen on washing machines and refrigerators. The new label must contain precise details with seven grades (A-G) of fuel efficiency, wet grip and exterior noise when in motion (in dB), respectively.

View ProductModel 5300 Series Pail/Drum Label Printer-Applicator

The fully-automatic system that quickly and accurately prints and applies labels to pails or drums on the production line.

• Fully automatic pail/drum labelling system

• Ideal for rough production conditions

• High-grade label printing in a single operation

• Prints and applies labels up to 7″ x 14″

• Labels up to 30 products per minute

• Print resolution up to 600 dpi

• All conventional data interfaces

• Service interval display

• Display controller for simple operation

• Easy integration

• CE certification

Weber LA 4050 P

Two-sided labeling LEGI-AIR 4050 P allows the labeling of two adjacent sides of a pallet. Up to 7 pallets can be processed per minute, depending on the application. Variable data (e.g. text, barcode or logo) are printed precisely and legibly on the labels immediately before the application procedure. The labels are subsequently applied using swing-arm […]

View Product