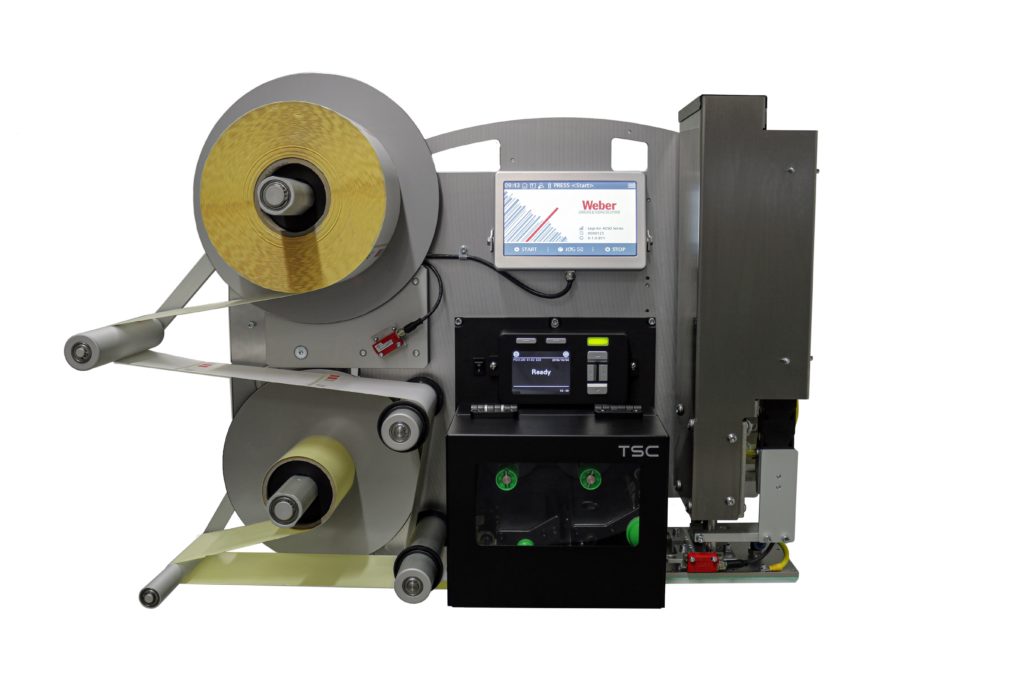

Weber LA4050B-EL – All Electric Linear Print Apply System

Weber’s LA4050B Series Electric Labelling Print and Apply automated labeling systems feature industry-leading smart technology that use sensors to reduce label application complications, ensuring a one-to-one label-product match. As the leading all-electric Label Printer/Applicator manufacturer on the market, our pressure sensitive labeling systems enable customers to completely replace conventional pneumatic systems with semi-electric and or a fully electric option that controls the label with pinpoint accuracy in side, top, bottom and corner-wrap applications throughout the packaging process.

The Weber LA4050B EL (Electric Linear) is an efficient Printing and Label Application System providing up to a 25% increase in efficiency when compared to some traditional pneumatic Tamp Blow Labelling Systems. The Electric Linear Stroke System is capable of Printing and Application throughput in excess of 80 labels per minute (dependant on label size) with higher accuracy in terms of label placement and Liner Stroke positioning. The LA4050B EL is capable of applying labels to side, top or bottom of products. The Light weight design of the Stroke Unit allows for the a fast Tamp and Return Cycle. This allows for optimal label transfer time, without adding damaging force to the product. The system is designed for use with a variety of Print Engines such as Sato, Zebra, Datamax etc. from 203dpi to 600dpi Printing Resolutions. Typically used for Top and Side Case Labelling the Weber LA4050B EB can be used in a variety of Industries from Logistics and Warehousing to Food and Beverage. The System can also be used in conjunction with a Wipe Down Station for Corner Wrap Applications.

Like all Weber Labelling Systems the unit is modular in design with easy to remove unwinder, rewinder, and Print Engine in the event of a critical component failure. This provides significant benefits for 24/7 operation where  downtime is a cost critical factor. The choice of Print Engines add to the versatility of the System and provides label size ranges from 10mm x 5mm up to 180mm x 800 mm at a speed of up to 80 labels per minute (dependant on label size). The system has the same interface options (Alarm System, Error Control, Volt Free Output, M12 connection for Sensors etc.) as some of our other high end systems but with a low base cost. The all new Weber controller can manage the functions of the Labelling System with ease and simple to use touchscreen GUI.

downtime is a cost critical factor. The choice of Print Engines add to the versatility of the System and provides label size ranges from 10mm x 5mm up to 180mm x 800 mm at a speed of up to 80 labels per minute (dependant on label size). The system has the same interface options (Alarm System, Error Control, Volt Free Output, M12 connection for Sensors etc.) as some of our other high end systems but with a low base cost. The all new Weber controller can manage the functions of the Labelling System with ease and simple to use touchscreen GUI.

The system has a pivoting U-Arm which allows rotation of the system by 360 degrees allowing the Labelling System to Print and Apply a label to any side of a product including Base Labelling of Products. The system can be mounted on its own individual stand, integrated directly into a packaging machine as part of an automated packaging line or mounted directly on one of our many handling systems providing a turn key solution to your particular Labelling requirements.

Other Benefits include:

- Low Total Cost of Ownership

- High accuracy Labelling

- Versatility and Flexibility in Labelling Configuration

- Easily adaptable to changes in Production

- Low Running Costs

- RFID Upgradeable

- High Throughput 24 / 7 Operation

- Available in 4″ wide and 6″ Wide Print Widths

- UK Service and Support Network

Additional Options include:

- Low label Warning System

- Protective Enclosure for Harsh Environments

- Barcode Scanning Module

- RFID Print Engine

- Vision System

- Choice of Product Detection Sensors

- Bespoke Handling Systems available

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

LPA_TIN_063D_LA_4050B_EL_GBZD500R RFID Printers

Zebra ZD500R UHF RFID Printer Advanced features in a compact, easy-to-use device. The ZD500R extends Zebra’s broad range of RFID printers by adding UHF RFID printing and encoding to Zebra’s line of industry-leading thermal desk top printers. Designed for applications where space is at a premium, the compact ZD500R offers simple, one-touch printing and encoding, straightforward loading, and automatic RFID calibration, making it ideal for applications where technical support staff is not available, such as retail in-store exception tagging.

View ProductWeber LA2050 – Compact Entry Level Print & Apply

The compact and low-cost LA2050 label print and apply system is designed for automated print and apply processes on a production line. It can also be used in semi-automatic mode where automatic label application is not required with the system being used as a label print and dispense system, with the label applicator system being initiated manually by the operator.

View ProductGeset 117 Top and Bottom Labelling System

The Geset 117 labelling system is used to label square products on the top and bottom side automatically. Depending on the type and dimension of the product, different label sizes are used. The products are fed manually or by a conveying system provided by the customer at an infeed passage on the labelling system. Care should be taken on accurate alignment of the products. It is essential that the products are forwarded separately to the applicator with a gap between each other.

When the light barrier is reached, an application trigger is tripped. Both label applicators apply then in Wipe On procedure a label onto the product. The label on top side is pushed on the product by a brush or roller. The label on bottom side is pushed on the product by the self-weight of the product. After labelling the products move on and can be removed from conveyor by the customer.

View ProductAlpha Compact Pre-Printed Labelling System

Our Alpha Compact Range of Labelling Systems, Compact, Lightweight, Durable and Easy to Use.

View Product