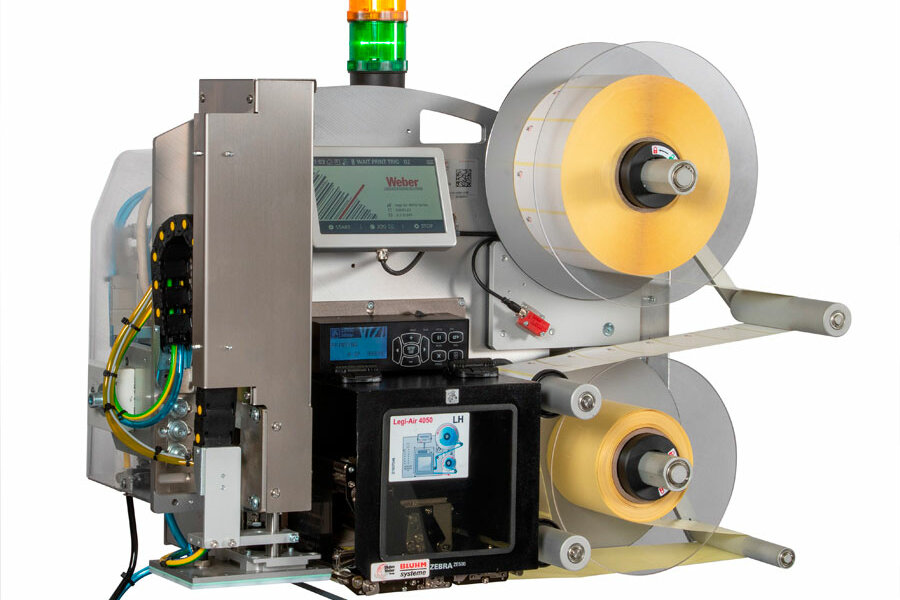

Weber Legi-Air 4050E Generation 3 Print Apply System

The Weber Legi-Air 4050E Generation 3 is the latest offering by Weber Packaging Solutions of the 4050 Labelling Systems range. It has the reliability and modularity of its predecessor the LA4050E Version 2 but with on board Intelligence and an enhanced User Interface. In the design of this system Weber has focused on reliability, connectivity, efficiency, and versatility.

With over 15,000 Weber LA4050E Systems installed worldwide we have redesigned and enhanced our best selling product to bring you the latest generation of the 4050 Labelling Systems range. Using the latest technology the Generation 3 LA4050E provides all the reliability of its predecessor but with design features and enhanced connectivity which provides a universal solution to your automation needs.

System Design: The System is modular in design consisting of a powered unwinder, rewinder, applicator module and printer module, which reduces downtime in the unlikely event of a component failure. It has a lightweight chassis that is easy to reconfigure for integration into tight workspaces and easy access to components for shorter service intervals. The System has a pivoting U-Arm mounting which allows the system to be rotated on its X and Y axis for Top, Bottom, and Side Apply making it easy to reposition to suit your individual requirements.

Enhanced Connectivity: Weber’s Legi-Air 4050 E Gen3 is equipped with an optional Logic Controller and all necessary interfaces for automation, allowing to connect to other systems via Fieldbusses or OPC/UA. It comes with all of the standard communication interfaces for data transfer to the Print Engine and on board IOT to gather system data including an ultra-modern touchscreen display to make configuration and management more user-friendly.

Versatility: The System comes with a choice of Print Engines giving you flexibility in your choice of Printer and with this the added benefit of a choice of Print Resolutions from 200dpi to 600dpi to suit your printing needs. The system easily adapts to changes Product Surfaces with a choice of Label Application options and Label Sizes from 10mm x 5mm to 173mm x 350mm. Our Application Modules provide over 1800 configurations for Dual and Single Label options.

Efficiency: Our latest Generation 3 Systems all come with enhanced pneumatics that provide greater Labelling Accuracy at speeds of up to 400mm per second. The latest technology in vacuum modulation means that the system can operate at a greater level of efficiency with lower air consumption which saves energy and running costs for your business.

Service and Support: Our Worldwide network of Distributors and Weber manufacturing sites gives you the peace of mind knowing that you have dedicated technicians available with 24/7 support through our network of partners making us a Global Supplier for Global Companies.

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

Legi-Air 4050E Gen3_optLegi-Air 4050E Gen3 data sheet_opt

- Choose from a wide range of 203, 300 and 600 dpi print engines

- Capable of handling print speeds up to 16 ips

- Numerous I/O’s ease interfacing with external devices

- Monitor operation via a web browser

MC67 Mobile Computer

Give your field workforce customers the tools they to work faster and smarter than ever before with the MC67

What can your customers accomplish with the MC67? Everything they need to get the job done. Your customers can choose the operating system that best supports their mobility strategy — Windows® Embedded Handheld 6.5 or Android™ Jelly Bean (4.1) — to instantly access the wealth of information in their business systems to increase task efficiency and accuracy. This fully-featured powerhouse of a device lets workers access information in the backend system; scan practically any bar code in almost any condition; capture documents to simplify recordkeeping; take and send video and photos for real-time repair support; and call a customer with an arrival window — all at 4G HSPA+ speed.

View ProductModel 5300 Series Twin-Tamp Label Printer-Applicator

Weber’s Model 5300 Twin-Tamp label printer applicator combines a high-performance thermal/thermal-transfer label printer with a specially configured applicator to satisfy the printing and two-label, adjacent-panel application of carton labels in line.

Portable Print & Ship

The Barcode Reader – efficiency in the form of a device

The “Portable Print & Ship” solution utilises a new kind of small handheld reader. The device can scan barcodes and it also contains a read/write unit for tags.

ZQ500 SERIES Mobile Printers

Extreme environments and bangs and bumps are no match for these lightweight, compact printers. Zebra’s ZQ510™ and ZQ520™ printers are the most rugged printers available. They perform in the widest operating temperature range in the industry and can withstand repeated drops to concrete from up to 6.6 feet. Water spray is no match with their IP54 rating. Featuring Zebra’s Link-OS® environment, these premium printers are easy to integrate, manage and maintain. With large buttons and a user-friendly interface, they are easy to operate, even when wearing gloves.

View Product