XB4Jet/XB8Jet

The compact and robust controllers XB4JET and XB8JET are used to control the inkjet printheads for product marking solutions. The following Markoprint printing technologies are supported: Hewlett-Packard, Funai, Trident.

- Simultaneous marking of primary and secondary packaging using a controller

- Printing on up to two production lines with the XB4JET and up to four production lines with the XB8JET

- Perfect for fixed installation in control cabinets as it offers full remote control capabilities through different interfaces

- Print layout can be designed using the iDesign software included in the scope of delivery

- Print layouts are sent to the XB4JET and XB8JET using the network connection, EIA232, USB interface or a USB stick

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

XB4JETXB8JET

Axicon 12000 2D Barcode Verifier

The Axicon 12000 2D verifier is designed to give repeatably highly accurate results when verifying Datamatrix and similar barcodes. The Axicon 12000 conforms to all of the latest ISO, GS1 and Pharmaceutical standards – and the Axicon 12000 has pioneered the AI content checking for the different pharmaceutical requirements (CIP, Turkish Ministry of Health, etc). The Axicon 12000 is designed for all 2D barcodes where an aperture size of 3mil or more is required (up to the scan area available – see scan area details overleaf) – the user can set the aperture either directly or by specifying a required Application Standard.

View ProductNursery Labels

Weather Resistant labels need to be able to handle exposure to all types of weather conditions plus direct sunlight and constant watering. Our polytag material can stand up to the job plus you can print variable information on-site with our thermal label printers equipped with durable thermal ribbons. Our garden labels come in lots of shapes and sizes, and can be used for custom printing. We can customize your labels with pre-printed logos and graphics.

View ProductMarkoprint ZTV HP

The Markoprint ZTV HP is a Central Ink Supply (CIS) system stores up to 400ml of ink for Markoprint HP Class inkjet printing systems such as the Markoprint integra One, Markoprint X2JET / X4JET, and Markoprint integra Quadro.

The large ink tank prevents frequent cartridge replacements from lowering your Overall Equipment Effectiveness (OEE). It can hold up to four single HP cartridges repaying you rapidly thanks to reduced ink prices. For non-interrupted production, the system can be paired with our NonStopPrinting printhead. Using an interface directly on the cartridge, current ink filling levels are monitored in real time. When the levels in the bulk tank fall below a certain threshold, a valve to the bulk tank opens and automatically refills it.

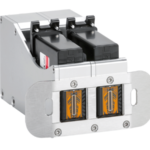

View ProductMarkoprint NonStop Printing

To enable continuous marking in ongoing production, our Markoprint NonStopPrinting printhead holds two alternately printing cartridges. Because the other ink cartridge is printing on the same position, each ink cartridge can be changed, cleaned, or serviced without pausing the machine.

An intelligent automatism prevents both cartridges from going empty at the same time. The first cartridge will always print two consecutive print jobs, taking turns with the second cartridge, which will only print one. This sophisticated automatism avoids both cartridges from running out at the same time. This will keep the ink from drying out in both cartridges. When the cartridge with the larger print volumes is empty, a warning will show, and the other cartridge will continue printing until it is replaced. The new cartridge will print the lower quantities to allow for you to replace the “older” cartridge. A sophisticated workflow that will boost your efficiency and productivity.

View Product