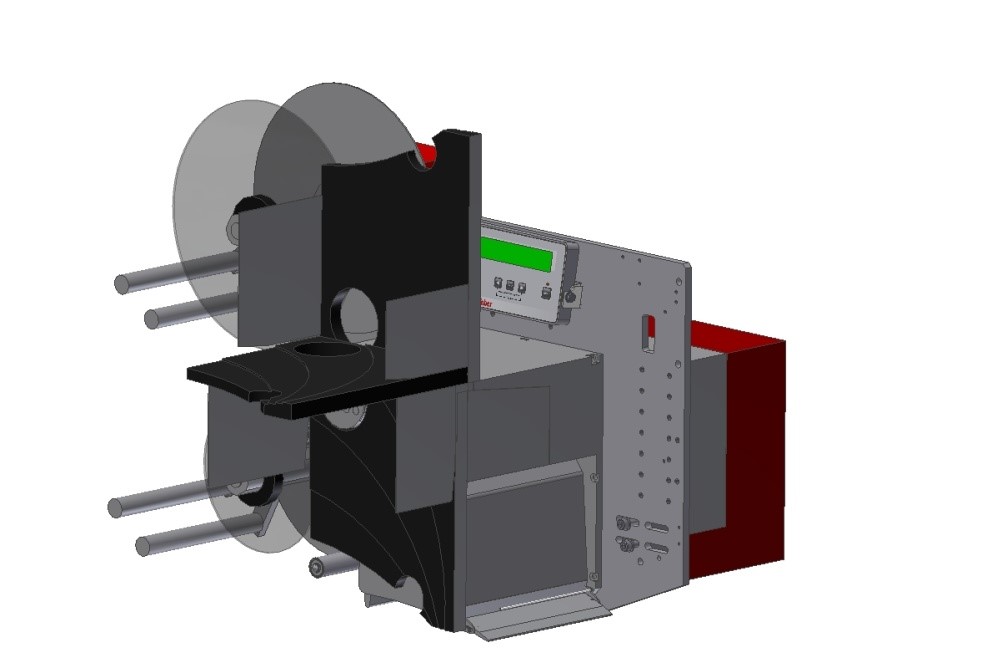

Weber LA4050WO – Wipe On Printer Applicator

The Weber 4050WO is a simple low cost Wipe on label applicator which comes with a choice of Print Engines dependent on the customers requirements. This system is suitable for Top, Bottom, or Side Labelling of Flat Surfaces with a choice of Dispensing Beaks to cater for any Labelling Challenge. The System is easy to integrate into an existing Line or as a Standalone Labelling System mounted on its own Stand.

The Weber LA4050 WO Provides a cost effective and efficient means of Printing and Application in one Sequence providing up to a 25% increase in throughput when compared to some Tamp Blow Labelling Systems. The system is designed for use with an Avery Print Engine with its own integrated dispensing beak but also comes with an optional additional Dispense beak permitting the user to fit other Print Engines such as Sato, Zebra, Datamax etc. in 203dpi and 300dpi Printing Resolutions. Typically used for Top and Side Case Labelling the Weber 4050 WO can be used in a variety of Industries from Logistics and Warehousing to Food and Beverage.

It is primarily designed with simplicity in mind and provides a robust reliable means of Labelling without the need for air supply like other systems currently on the market. Despite its basic design it provides the same high  speed Printing and Application with label ranges from 10mm x 5mm up to 180mm x 800 mm at a speed of up to 250 labels per minute (dependant on label size). The system has the same interface options (Alarm System, Error Control, Volt Free Output, M12 connection for Sensors etc.) as some of our other high end systems but with a low base cost. The basic controller can manage the functions of the Labelling System with ease and simple to use menus.

speed Printing and Application with label ranges from 10mm x 5mm up to 180mm x 800 mm at a speed of up to 250 labels per minute (dependant on label size). The system has the same interface options (Alarm System, Error Control, Volt Free Output, M12 connection for Sensors etc.) as some of our other high end systems but with a low base cost. The basic controller can manage the functions of the Labelling System with ease and simple to use menus.

The system has a pivoting U-Arm which allows rotation of the system by 360 degrees allowing the Labelling System to Print and Apply a label to any side of a product including Base Labelling of Products. The system can be mouunted on its own individual stand, integrated directly into a packaging machine as part of an automated packaging line or mounted directly on one of our many handling systems providing a turn key solution to your particular Labelling requirements.

Other Benefits include:

- Low Total Cost of Ownership

- High accuracy Labelling

- Versatility and Flexibility in Labelling Configuration

- Easily adaptable to changes in Production

- RFID Upgradeable

- High Throughput 24 / 7 Operation

- Available in 4″ wide and 6″ Wide Print Widths

Additional Options include:

- Low label Warning System

- Protective Enclosure for Harsh Environments

- Barcode Scanning Module

- RFID Print Engine

- Vision System

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

LPA_TIN_056D_LA_4050_WO_GBPressure-Sensitive Automotive Parts Labels

Heavy-duty labels that look good. Labels used in the automotive parts industry have to be tough to stand up to the harsh environments where they are used. But that doesn’t mean they can’t look good, too. Bright, colorful consumer parts labels need to add life and value to your packaging while OEM parts need durable […]

View ProductMarkoprint Integra Vivid

Unleash the Power of Modern Touch Operating Technology and an Innovative Swipe User Interface. Say Goodbye to Complicated Print Jobs and Say Hello to Effortless Operation of X1JET and PP Class Printing Systems. With the Freedom to Position the 7” High-Resolution HMI Color Display Anywhere You Choose, Prepare to Be Awed by the Ultimate Printing Flexibility and Innovation. Upgrade to integra Vivid Today and Embrace a New Era of Printing Excellence.

View ProductEpson GP-M831 Printer

Offering a more flexible alternative to dot matrix technology, the GP-M831 combines the sturdiness of a dot matrix printer with the advantages of inkjet, such as wider media compatibility and higher-quality prints. Unlike dot matrix printers, the versatile GP-M831 can print advanced barcodes and crisp text, and can be used with a variety of media, including glossy paper and labels.

View Product

Zebra DS4800N Compact Laser Scanner

DS4800 is an industrial laser scanner combining flexibility and compactness thus satisfying all application needs of the production plant.

Through the smart focus adjustment DS4800 optimizes the performances based on the reading distance. This extends the reading area and

improves the overall read rate.

View Product