Tamper Evident

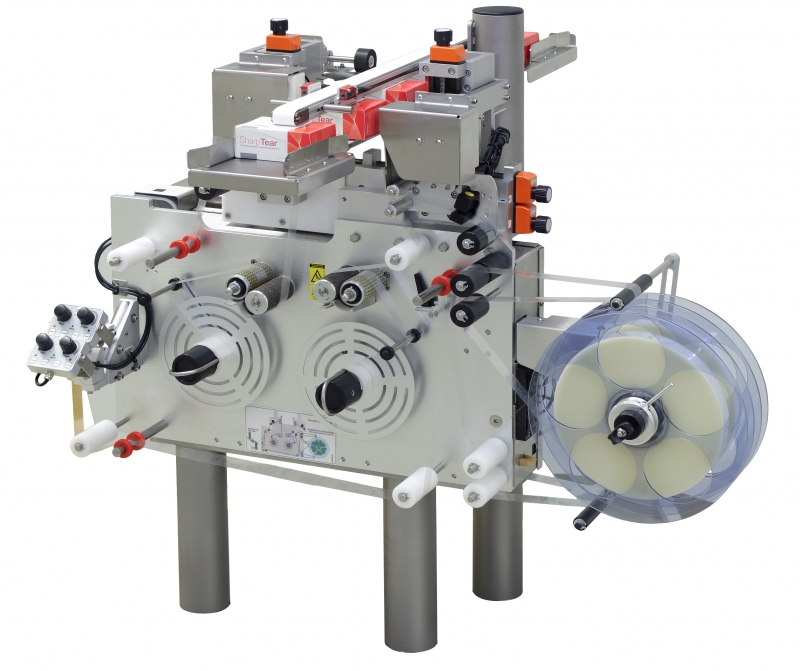

Weber’s Tamper Evident OEM module is specifically designed to fit neatly into existing Serialisation or Pharma Packaging Systems.

Tamper Evident Labelling Module

The EU Directive 2011/62/EU introduced legal framework requirements for a pan-European safety system for prevention of counterfeit medicines. A central component, which is also addressed in the pharmaceutical law, is a clear and secure marking system for database-backed traceability and tamper-proof sealing of all packaging. Weber can offer a compact, efficient and reliable solution to this requirement. A compact labelling unit is integrated into existing or newly configured Pharma Packaging Systems. A tamper evident label is applied to each end of the carton providing a secure seal which is checked by sensors. The data from all correctly serialized cartons is memorized using the track and trace software allowing each unique pack to be traced back to the manufacturer at any point in the supply chain.

Each individual carton is printed with a unique identity and 2D matrix code produced by sophisitcated track and trace software, which is linked to a vision system. In the event that the vision system detects a mis coded product the system can be configured for use with a Reject Station to dispose of the product.

As this solution is specifically designed for OEM Integration it has a small footprint for ease of installation and configuration. Maintenance and Label Reel change downtime is minimised due to the specific design of the system.

Special Features

- Sealing labelling for protection against counterfeits

- Two-sided corner labelling of folding boxes

- Highly compact design to allow integration into existing plant

- Output clocking up to 300 items per minute

- Stepper motor driven applicator

- Short set-up times when switching to other product formats

- Processing of transparent, perforated labels

- Speed-independent labelling via Tamp-Wipe-On method

- Dual label roll unwinding

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

ManufacturingArmor AWR470 Thermal Transfer Wax Ribbon

AWR®470 SolFree® is the only ribbon in the world to be coated without using solvents, including for the backcoating. SolFree® represents a saving of 365g of CO2 compared to the same ribbon (with average dimensions) produced with a traditional process for the backcoating. AWR®470 SolFree® is well known for its high coverage ability which is essential for printing the rough materials widely used in logistics.

View ProductChecker 4G Series

Checker Vision Sensor Features

The Checker® vision sensor is an award winning all-in-one industrial sensor with built-in camera, processor, lighting, optics, and I/O capable of detecting and inspecting up to 6,000 parts per minute–all in an industrial IP67 enclosure small enough to fit into the tightest of spaces.

View ProductPressure-Sensitive Spice Labels

Exotic spices need to have labels that reflect the quality and specialty of the product. And you need to create a unique look for your spice family so customers will look for the familiar package when they buy again. A good label design will entice customers to try your brand. By using metallic foils and gloss/dull varnish combinations, your labels can become a work of art.

View ProductGeset labelling machine – Geset 300