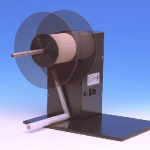

Model 5300 Series Dual-Label Pallet Label Printer-Applicator

Weber’s Model 5300 Dual-Label pallet labelling system combines a high-performance thermal/thermal-transfer label printer with a specially-engineered articulating swing-tamp applicator to perform the printing and two-label, adjacent-side labelling of pallets in-line.

- Choose from a wide range of 203, 300 and 600 dpi print engines

- Capable of handling print speeds up to 16 ips

- Numerous I/O’s ease interfacing with external devices

- Monitor the labeller’s operation via a web browser

- Available with optional RFID capability

- An easy way to add a two-sided labeller after your palletiser system

Model 5300 Series Dual-Label Pallet Label Printer-Applicator

Designed and manufactured by Weber, the Dual-Label pallet labelling system features a selection of print engines, which includes 203, 300 or 600 dpi units from manufacturers like Zebra Technologies, SATO and Datamax. Print engines are available to handle pallet label sizes ranging from 4.0″ wide and up to 8.0″ long.

All systems print pallet labels with variable-sized text, bar codes and/or graphic images. Various print speeds are programmable at up to 16 ips.

As a label is printed, it is automatically peeled from its liner and retained by vacuum on a non-contact, tamp-blow applicator pad. The articulating tamp pad is mounted on a pneumatically-operated swing arm that reaches across the leading side of a pallet as it approaches the Dual-Label unit via conveyor. When the pallet is in position, a sensor mounted on the swing arm detects the pallet and the label is gently blown onto the lead panel of the pallet.

The swing arm then retracts to collect a second printed label which is followed by an articulated stroke that blows the label onto the adjacent side of the pallet to complete the cycle. Depending on the combination of label print engine, pallet size, conveyor speed and the proximity of the Dual-Label system to the pallet, up to five pallets per minute can be labelled.

Special Features & Options

This Model 5300 Dual-Label pallet labelling system includes a number of noteworthy features that add to the operational versatility of this printer-applicator:

• Browser-based monitoring: The status of all operational functions and configurations can be monitored by logging on to a web page that is unique to each Model 5300 unit.

• Numerous I/O’s: The system can be interfaced with many types of external devices.

• One-to-one media consumption: Special label unwind and rewind dimensions are matched to the system’s ribbon supply to ensure they are consumed at the same rate, reducing downtime and eliminating partial changeovers.

• Print job storage: Multiple label printing formats can be stored in the system’s memory, making it easier for an operator to select a job directly from the applicator instead of downloading a computer file.

The Model 5300 system boasts numerous additional features including a microprocessor controller with downloadable firewall capability, various inputs/outputs, plus durable construction that will withstand harsh industrial environments.

Other options include a 15-foot umbilical connection that enables the remote location of the unit’s controller, an adjustable stand for optimum system orientation, label-on-pad sensor for added functionality plus beacon light alerts to signal the status of label and ribbon supplies.

To facilitate routine maintenance, the system is programmed with built-in machine cycle diagnostics for self-testing of normal operating cycles plus input diagnostics that permit testing on specific functions.

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

5300_pallet_dual_label- Auto-switching Universal Power Supply for immediate adaptability anywhere in the world

- Compatible with all Direct Thermal and Thermal Transfer printers

- Electronic Speed Control will automatically synchronise winding speed to the speed of your printer

- Provides passive winding without skewing print or barcodes on your labels

- Rewind up to 61cm per second

- Easily handles labels up to 23cm wide

- Wind labels face in or face out

- Print speed up to 305 mm per second

- Left or right handed available

- Robust industrial design

- Easy Connectivity

- Especially for Print & Apply designed systems

- RFID ready!

Electric Rewinder Models GLU-100 & Model GLR-100

Nursery Labels

Weather Resistant labels need to be able to handle exposure to all types of weather conditions plus direct sunlight and constant watering. Our polytag material can stand up to the job plus you can print variable information on-site with our thermal label printers equipped with durable thermal ribbons. Our garden labels come in lots of shapes and sizes, and can be used for custom printing. We can customize your labels with pre-printed logos and graphics.

View ProductSato M84Se Printer

FEATURES

NAUTIZ ETICKET PRO II

MOBILE TICKETING MADE EASY

A smart choice for electronic fare collection and ticket validation, the Nautiz eTicket Pro II merges ultimate mobility with true field functionality. This rugged handheld is a reliable and efficient tool for mobile ticketing, transactions and validations, designed specifically with transit workers in mind — it’s packed with features, it’s compact and truly portable, and it offers a reliable computing solution for challenging worksite environments.

View Product