Model 5300 Series Air-Blow Label Printer-Applicator

This Weber exclusive provides high-resolution printing and high-speed operation combined with the dependable air-blow method of label application.

•Choose from a wide range of 203, 300 and 600 dpi print engines

•Capable of handling print speeds up to 16 ips

•Numerous I/O’s ease interfacing with external devices

•Monitor operation via a web browser

•Available with RFID capability

Model 5300 Series Air-Blow Label Printer-Applicator

Weber’s Model 5300 air-blow module provides an accurate, versatile means of pressure-sensitive label printing and non-contact application.

In addition to offering a broad selection of high-quality print engines that feature various print resolutions and label dispensing rates, this Model 5300 system is available with optional RFID print-encode engines.

Standard direct and thermal-transfer print engines from manufacturers Zebra, SATO and Datamax produce text, bar codes and graphic images at 203, 300 or 600 dpi. The Zebra-based RFID models combine these printing capabilities with the encoding and verification of RFID inlays to meet EPC Gen 2 protocols.

Special Features & Options

The Model 5300 air-blow system includes a number of noteworthy features that add to the operational versatility of this printer-applicator.

• Air-blow application: This method of air-assisted, fixed-distance label placement can be used with standard applications. A printed label is fed into place and held by vacuum, then it is blown onto a product or package to a placement accuracy of ±0.03″.

• Air-blow application: This method of air-assisted, fixed-distance label placement can be used with standard applications. A printed label is fed into place and held by vacuum, then it is blown onto a product or package to a placement accuracy of ±0.03″.

• Browser-based monitoring: The status of all operational functions and configurations can be monitored by logging on to a web page that is unique to each Model 5300 unit.

• Numerous I/O’s: The system can be interfaced with many types of external devices.

• One-to-one media consumption: Special label unwind and rewind dimensions are matched to the system’s ribbon supply to ensure they are consumed at the same rate, reducing downtime and eliminating partial changeovers.

• Print job storage: Multiple label printing formats can be stored in the system’s memory, making it easier for an operator to select a job directly from the applicator instead of downloading a computer file.

The Model 5300 air-blow system boasts numerous additional features including an upgradeable microprocessor controller, various inputs/outputs, plus durable construction that will withstand harsh industrial environments.

There are also several optional enhancements that can increase the system’s functionality. A product height sensor, for example, enables the printer-applicator to label items of varying heights delivered by the same conveyor.

Other options include a 15-foot umbilical connection that enables the remote location of the unit’s controller; an adjustable stand for optimum system orientation; label-on-pad and product-presence sensors; plus beacon light alerts to signal the status of label and ribbon supplies.

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

5300EasyGo! ToDoCheckList

Summary

Perform your tasks and control the results with this simple but powerful application. Use the sorting areas and groups features to arrange and dispatch tasks to be performed by the operators. Go through work-flows, perform each task and mark the result of finished tasks.

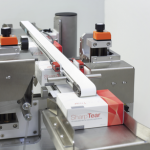

View ProductGeset 117 Top and Bottom Labelling System

The Geset 117 labelling system is used to label square products on the top and bottom side automatically. Depending on the type and dimension of the product, different label sizes are used. The products are fed manually or by a conveying system provided by the customer at an infeed passage on the labelling system. Care should be taken on accurate alignment of the products. It is essential that the products are forwarded separately to the applicator with a gap between each other.

When the light barrier is reached, an application trigger is tripped. Both label applicators apply then in Wipe On procedure a label onto the product. The label on top side is pushed on the product by a brush or roller. The label on bottom side is pushed on the product by the self-weight of the product. After labelling the products move on and can be removed from conveyor by the customer.

View ProductZebra DS4308-HC HEALTHCARE SCANNER

In the mission-critical world of healthcare, caregivers need to be able to accurately capture virtually any barcode, on any medium, in any condition — with first-time every time predictability. And with the DS4308-HC on your workstations-on-wheels and other carts, they can. The DS4308-HC does it all — 1-D or 2-D, electronic or printed on paper labels, tiny dense codes on the curved surface of a vial, codes printed on reflective surfaces like IV bags, codes under shrink wrap on doses of medication — and even smudged, scratched or poorly printed barcodes. The result? The priceless peace of mind that the right patient received the right medication and the right test results, every time.

View ProductTamper Evident Label Applicator

A core requirement of the European Directive 2011/62/EU that will come into force by 2016 is to equip the outer packaging of medicals with a tamper evident feature. Which should ensure the customer that he is the first opening the package.

View Product