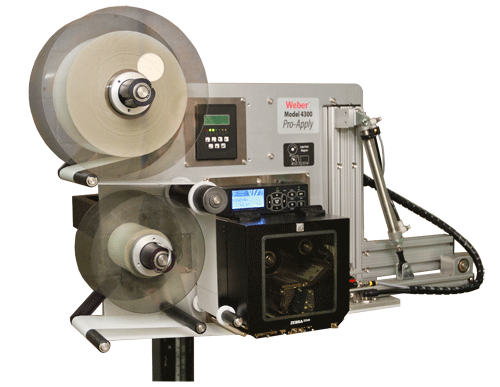

Model 4300 Pro-Apply Swing-Tamp Label Printer-Applicator

Weber’s economical Model 4300 Pro-Apply swing-tamp printer-applicator features the functionality often limited to higher-duty production systems used to label the leading or trailing side of a product.

• Applies labels up to 6″ wide x 6″ long

• Prints text, bar codes and graphic images @ 203, 300 or 600 dpi

• Non-contact, swing-tamp application

• Accurate labeling to within ±0.03″

Model 4300 Pro-Apply Swing-Tamp Label Printer-Applicator

The Model 4300 Pro-Apply Swing-Tamp is a versatile in-line system that combines high-quality label printing and application that ensures the fast, accurate pressure-sensitive labelling of the leading or trailing side of a product along the production line.

The Model 4300 Pro-Apply system is designed and engineered by Weber and is assembled in our own U.S. manufacturing facility. Each unit is equipped with an on-demand, thermal/thermal-transfer print engine from Datamax, SATO or Zebra to produce 203, 300 or 600 dpi text, bar codes and graphic images at speeds up to 16 ips.

Labels up to 6″ wide and 6″ long are printed in a cost-efficient, next-out mode, and then are instantly applied to cartons or products on the production or packaging line.

Utilising the swing-tamp method of application, a printed pressure-sensitive label is automatically peeled from its liner and is retained by vacuum on the applicator’s tamp pad. The unit’s 90-degree swing arm then extends to apply the label, blowing it on to the package from approximately 0.25″.

Several standard tamp-pad sizes are available and are provided in quick-change configurations. In just a few seconds the tamp-pad can be removed and another fastened in its place to handle a different size label.

Standard features include durable anodized aluminium construction, an integrated user interface with LCD display, and numerous inputs/outputs to facilitate the use of a product sensor or other optional accessories and stepper motor-driven rewind.

In addition, system components are readily accessible to ease service and all units feature zero-downtime connectivity to ensure uninterrupted production.

Options include a variable stroke sensor, a label-on-pad sensor and an adjustable stand that enables the system to be oriented for top, bottom or side application.

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

4300- Heavy Duty Industrial Construction

- High Resolution Printing

- Interface Port for Easy Connectivity

- Materials Tracking

- Work-in-Process

- Easy Loading

- Choose from a wide range of 203, 300 and 600 dpi print engines

- Capable of handling print speeds up to 16 ips

- Numerous I/O’s ease interfacing with external devices

- Monitor operation via a web browser

- Available with RFID capability

Zebra DS4308-HC HEALTHCARE SCANNER

In the mission-critical world of healthcare, caregivers need to be able to accurately capture virtually any barcode, on any medium, in any condition — with first-time every time predictability. And with the DS4308-HC on your workstations-on-wheels and other carts, they can. The DS4308-HC does it all — 1-D or 2-D, electronic or printed on paper labels, tiny dense codes on the curved surface of a vial, codes printed on reflective surfaces like IV bags, codes under shrink wrap on doses of medication — and even smudged, scratched or poorly printed barcodes. The result? The priceless peace of mind that the right patient received the right medication and the right test results, every time.

View ProductMC1X PERSONAL SHOPPER

ACHIEVE CUSTOMER SERVICE EXCELLENCE AND ASSOCIATE PRODUCTIVITY

Add value to the customer experience with targeted promotions and offers based on buying preferences. Empower store associates to more efficiently manage inventory and pricing at the shelf edge. Reduce your overhead costs and improve customer loyalty with the MC Series multi-function retail mobile computer.

View ProductSato LM4e Strong AND Durable Printer

FEATURES

Model 5300 Series Swing-Tamp Pallet Label Printer-Applicator

This Weber exclusive provides high-resolution printing and high-speed operation combined with the swing-tamp method of label application that affixes a label to the leading or trailing side of a pallet load.

View Product