Medical Device Labels

High standards and dedicated inspection for quality assurance. Medical device labels require strict quality control during every step of the manufacturing process. On-press and post-press video inspection guarantees finished labels that meet your requirements.

Weber has complex die and adhesive zone coating capabilities to permit one-step labeling for product kit combinations. And our on-press, code dating and messaging using laser etch or UV inkjet allows the addition of variable data during printing. Sequential back-of-liner numbering aids your lets you keep your inventory under control.

Medical Device Label Tips

Materials:

- Use adhesives and topcoats that are compatible with your sterilization process.

- Provide more information to your end users by adding expanded text and multi-ply label constructions that can handle the demand for increased text area on the label.

Artwork:

- Add a laminate or spot varnish to areas of your label to highlight specific features or allow variable thermal-transfer printing.

- Custom die cuts and layering lets you add individual peel-able bar codes for record-keeping.

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

X4Jet Plus

With the new high performance Markoprint X4JET print controller, different inkjet printing technologies can be controlled either simultaneously or alternately. The intuitive input unit of the new high performance Markoprint X4JET plus print controller is a boost to operator convenience. All system parameters can be entered easily and quickly, to be stored and called up later.

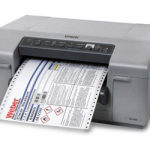

View ProductEpson ColourWorks™ GP-C831 Inkjet Colour Label Printer

Epson’s ColourWorks C831 breakthrough industrial-strength inkjet label printer is ideal for GHS large format drum and chemical labels. This wide-web printer uses pin-feed labels for extended accuracy.

View ProductZebra DS4308-HC HEALTHCARE SCANNER

In the mission-critical world of healthcare, caregivers need to be able to accurately capture virtually any barcode, on any medium, in any condition — with first-time every time predictability. And with the DS4308-HC on your workstations-on-wheels and other carts, they can. The DS4308-HC does it all — 1-D or 2-D, electronic or printed on paper labels, tiny dense codes on the curved surface of a vial, codes printed on reflective surfaces like IV bags, codes under shrink wrap on doses of medication — and even smudged, scratched or poorly printed barcodes. The result? The priceless peace of mind that the right patient received the right medication and the right test results, every time.

View ProductDNP R300 General Purpose Resin Ribbon

DNP has the most elite resin ribbon offering in the industry. R300’s extensive label adaptability and high print speed capability makes it the most diverse resin of its kind. It outperforms the competition in abrasion and solvent resistance, uses less print energy and is designed with DNP’s standard anti-static and backcoat properties to protect printheads and extend printhead life. And, like all DNP ribbons, R300 is an industry leader in Edge Definition™ producing dark, dense images for improved scan rates.

View Product