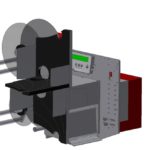

Legi-Air 5300

Label printer and dispenser for all labelling tasks

The new Legi-Air 5300 from Bluhm Systems is a modular Label printer and dispenser distinguished by its extremely versatile applications and a very high operating run time. In addition, the system offers a high degree of operator-friendliness: the operator is supported in his work by several functions such as service interval or operating condition display.

The Legi-Air 5300 is equipped with a variety of applicators for the most varied of tasks such as linear, rotation or corner applicators and also double-sided labelling. This guarantees the highest possible flexibility. Various label application methods are also possible including the tamp-blow and blow-box method for no-contact high speed labelling. For label printing there is a choice of industry-proven printing modules by many manufacturers. RFID printing modules for programming of radio chips are also available.

Legi-Air 5300: brilliant and high resolution

The system requires only one step to print the labels in brilliant and high resolution with a positional accuracy of up to ± 0.5 mm, or writes to RFID tags, with the information changing as required. Printing instructions can be stored directly in the system’s memory for easy handling, to be recalled again later by the operator. This enables working without a direct link to a PC.

Depending on applicator and application, label sizes of up to 180 x 500 mm can be processed and dispensing rates of up to 240 labels per minute are achievable. The system is suited for processing large label rolls with a maximum diameter of 350 mm (up to 600 m run length). In this way, it is not necessary to change the rolls as frequently and the operating run time is considerably increased.

Multilingual and user-friendly display

The multi-lingual plain language display is particularly user-friendly. It may be freely positioned in a way to best suit the operator even in constrained production environments such as under a conveyor system. Should there be a disruption such as the end of the working materials, the system can send an automatic report to an e-mail address previously specified by the operator.

The integrated service interval display will transmit a signal showing the next service date either to the conveyor system control or by e-mail. An integrated web browser can also be used to check the current service state. It is also possible to perform remote diagnosis via the browser.

The robust and enduring construction also renders the Legi-Air 5300 suitable for applications in rough production environments.

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

Legi-Air-5300-leaflet- Choose from a wide range of 203, 300 and 600 dpi print engines

- Capable of handling print speeds up to 16 ips

- Numerous I/O’s ease interfacing with external devices

- Monitor operation via a web browser

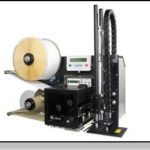

Legi-Air 4050 M Label printer and dispenser

Weber Packaging Solutions presents the Legi-Air 4050 M – a printing dispenser with a novel control concept. The “M” correspondingly stands for master controller: “The central hub for data and process control”.

View ProductWeber LA4050WO – Wipe On Printer Applicator

The Weber 4050WO is a simple low cost Wipe on label applicator which comes with a choice of Print Engines dependent on the customers requirements. This system is suitable for Top, Bottom, or Side Labelling of Flat Surfaces with a choice of Dispensing Beaks to cater for any Labelling Challenge. The System is easy to integrate into an existing Line or as a Standalone Labelling System mounted on its own Stand.

View ProductModel 5300 Series Twin-Tamp Label Printer-Applicator

Weber’s Model 5300 Twin-Tamp label printer applicator combines a high-performance thermal/thermal-transfer label printer with a specially configured applicator to satisfy the printing and two-label, adjacent-panel application of carton labels in line.

Weber Legi-Air 4050E – Precision Labelling System

Based on a modular construction the Weber 4050E is capable of numerous methods to print and apply a label. The design comprises a feeder module, a printing module, label winder and unwinder with numerous applicator types. The standard Tamp-Blow system has a quick-change system for changing the tamp pad which significantly reduces the changeover time to other label formats.

View Product