Bottle-Matic Label Applicators

Bottle-Matic bottle labelers enable you to label all kinds of products by simply inserting the container and depressing a foot-switch. Labels are applied at over 4.5” per second – most water bottles are labeled in less than two seconds. The operator then removes the bottle and inserts another to start the procedure again. These automated labeling systems make it easy to label wine bottles, craft beer bottles, water bottles and most other round products.

The Bottle-Matic has been developed to apply 1 or 2 labels (front & back) to a wide range of cylindrical containers including Bottles, Jars, Cans, Tubs and Tubes and is easily adapted to work with tapered, ridged & odd shaped containers.

Easy to set up and operate, making them an economical solution to relatively short runs and bespoke labelling.

The Bottle-Matic I is designed to apply 1 label to containers from a small patch to fully wrap around.

The Bottle-Matic II is an advanced model with the provision to apply 1 or 2 labels from the same roll, with a built in incremental dial to accurately space front and back labels on the same container.

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

Bottle-Matic EN Specification- Auto-switching Universal Power

- Supply for immediate adaptability anywhere in the world

- Compatible with all Direct Thermal and Thermal Transfer printers

- Electronic Speed Control will automatically synchronise winding speed to the speed of your printer

- Provides passive winding without skewing print or barcodes on your labels

- Rewind from 2.5cm to 25cm per second

- Easily handles labels from 2.5cm to 10cm wide

- Wind labels face in or face out

Zebra LS4208 – Handheld Scanner

LS4208 handheld laser bar code scanner, you’re able to effortlessly speed throughput, even with bar codes in poor condition. Wherever you need to quickly capture and process data — such as at the retail checkout counter, in pharmacies and hospitals, and in light warehouse environments — this ergonomically designed scanner helps you increase accuracy, improve productivity, cut maintenance

costs and reduce the risk of downtime.

Midrange Label Printers

Industrial labels are high-performance products for a broad range of business branches. They can be seen on everything, from beverage packaging, ink cartridges to automotive tyres. In production, logistics, stocktaking as well as trading, these symbols assist to deliver data and supporting advertising

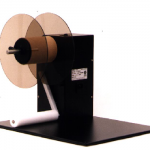

View ProductElectric Rewinder Model GLR-50

Industrial Label Printers – High Performance for High Demands

Weber Marking’s industrial label printers are the perfect solution for automatic printing and labelling. From small systems with a broad range of applications to high-end demands with specialised needs, every industrial label printer is durable and can operate to maximum efficiency.

View Product