SATO CT4 Series

At the core of the CT4i printers is a new generation ultra high speed processor.

CT408i | CT412i | CT424i

With high data transfer rates and processing speed the CT4i printers will print continuously, without pausing between labels, even with changes in data and graphics on every label. An important added feature of the CT4i Series printers is the Windows® driver which allows the creation of labels using virtually any Windows® based program

| Print Method: | Direct or Thermal Transfer |

| Print Resolution: | 203 or 305 or 609 dpi |

| Print Width: | 4.1″ |

| Media Width: | 1.1″ to 4.65″ |

| Memory: | 16MB SRAM/4MB Flash |

| Print Speed: (max.) | 6 ips (CT408i) 4 ips (CT412i) 3 ips (CT424i) |

Accessories

|

|

|

Applications

|

|

|

Industries

Aerospace |

Education & Libraries |

Healthcare |

Travel & Leisure |

Utilities |

Wholesale |

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

CT4 Data Sheet ENRF-Lite

Low-cost offline coding system; ideal for companies looking to automate their date marking process for the first time.

View ProductWater Bottle Labels

Make sure that you get the right label for your bottled water products. Water-proof film labels work best or, if recycling is important, you can go with a label material that is bio-degradable or easily removable for recycling.

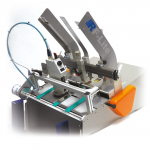

View ProductCode & Apply

“Code & Apply” extends the possibilities: the LA 4050 delivers tags in a single automatic process quickly and precisely, thanks to reliable pneumatic technology from Festo combined with vacuum and pressure measurement. Potentially defective tags can be rejected by using the optional “Bad Tag Reject” unit.

View ProductSunscreen Labels

Everyone uses sunscreen these days whether at the beach, playing sports outdoors, or at a family picnic. But how do you make your sunscreen product stand out from the hundreds of others on the store shelf? A simple, clean label design on a unique shaped container is the best way to get noticed. Bright colors and large characters for the SPF number are important considerations.

View Product