Legi-Air 5300 Tyre Label Printer-Applicator

Fulfilling EU Guidelines

According to an EU regulation all new tyres produced in or after January 2012 and placed on the market within the EU must bear a standardized EU label, such as those already seen on washing machines and refrigerators. The new label must contain precise details with seven grades (A-G) of fuel efficiency, wet grip and exterior noise when in motion (in dB), respectively.

Double Advantage

The Legi-Air 5300 Tyre label printer-applicator quickly and reliably labels tyres in accordance with the new regulation using tyre labels tailored to these requirements.

- Fully Automatic

- Ideal for rough production conditions

- High-grade label printing in a single operation

- Prints and Applies up to 24 dots/mm at 600 dpi

- All conventional data interfaces

- Service interval display

- Display controller for simple operation

- Easy integration

- CE certification

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

5300 RFIDLA4050E_uk

Weber Thermal-Transfer Ribbons

Weber’s long experience with thermal-transfer print technologies and compatible label materials has given us a broad understanding of exactly which ribbon is best suited for any application. Resin ribbons are suitable for very special applications. Each ribbon is formulated to print high-density bar codes, text and graphics for product identification, work-in-process, inventory control, shipping and other applications.

View ProductEpson C7500 High-Speed Inkjet Colour Label Printer

The Epson C7500 inkjet label printer is a fast, full-colour label printer whose rugged design allows minimal maintenance, low cost of ownership, and is ideal for busy, on-demand labelling environments.

The Just-in-Time Colour printing lets you print the labels you need, when you need them, quickly and economically. The C7500 uses durable inks that won’t smudge, smear or fade. And the highly durable labels are up to 50% lower in cost than laser or thermal-transfer printed labels.

View Product

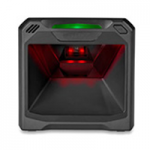

Symbol DS7708 Scanner

Easy to Deploy, High-Performance, “Can’t Miss” On-Counter Scanning

When it comes to on-counter scanning, the DS7708 scanner offers a feature set that puts it at the top of its class for performance, ease of use, easy deployment and total cost of ownership. With a large field of view that is over 50 percent larger than the competition, the DS7708 easily captures bar codes regardless of where they are located on an item. No matter what type of bar codes appear at the POS, the DS7708 can scan them all: 1D, 2D, printed and electronic.

View ProductPrimary labels / pre-printed labels

Brands and high-quality products need suitable labels to represent the image and reflect the branding. Weber Marking Systems is geared for the production of high-quality primary and pre-printed labels for any application.

View Product