RFID Smart Labels

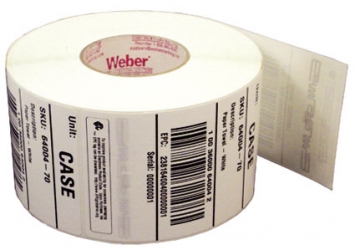

Weber is applying its expertise as a leading manufacturer and supplier of pressure-sensitive labels to provide the finest in RFID smart labels. Our innovative method of inserting the RFID inlays fits seamlessly within our label conversion process. And because we manufacture the RFID smart labels ourselves, we’re able to offer RFID media that will maximize performance and minimize costs.

Weber is an expert at manufacturing labels. We use the latest high-speed flexographic presses to produce rolls of blank and printed pressure-sensitive labels and tags.

Our innovative method of inserting the RFID inlays fits seamlessly within that conversion process. And because we manufacture the RFID smart labels ourselves, we’re able to offer RFID media that will maximize performance and minimize costs.

All SmartTrak RFID labels are produced using fully tested RFID inlays from trusted sources like Avery Dennison, Alien Technology, and UPM Rafsec. Every label is certified and verified to be the highest in quality.

Weber is a full-service, ISO 9001-registered labeling company. We do more than convert label material. We also are expert at recommending the right facestock and adhesive combination for a specific application.

Our facestock materials are available in thermal-transfer and direct thermal papers, film and other synthetic substrates – all of which can be provided in custom shapes and sizes – along with high- or low-tack adhesives. These are important considerations that can contribute to the overall success of an RFID smart label program.

Also critical is the selection of the optimum RFID inlay. We can help you determine which inlay will deliver the best performance for the intended application. And we’ll guarantee its performance.

RFID Printer-Encoders

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

RF-Lite

Low-cost offline coding system; ideal for companies looking to automate their date marking process for the first time.

View ProductZD500R RFID Printers

Zebra ZD500R UHF RFID Printer Advanced features in a compact, easy-to-use device. The ZD500R extends Zebra’s broad range of RFID printers by adding UHF RFID printing and encoding to Zebra’s line of industry-leading thermal desk top printers. Designed for applications where space is at a premium, the compact ZD500R offers simple, one-touch printing and encoding, straightforward loading, and automatic RFID calibration, making it ideal for applications where technical support staff is not available, such as retail in-store exception tagging.

View ProductSato GL4e Printer

The GL4e Series is SATO’s most significant release of printing technology to date. Versatility and value are the cornerstones of the GL4e Series with features that surpass the competition. Only the GL4e Series offers a field-upgradeable UHF RFID option; an industry-leading printer management utility SATOnet CONNECT™; standard tri-port communication protocols, competitive emulations and much more.

View ProductLS3408-FZ Scanner

HIGH-PERFORMANCE SCANNER WITH FUZZY LOGIC

Premium scanning for all 1D codes including poorly printed, damaged or low contrast bar codes or fast and accurate reading of damaged, dirty and poorly printed barcodes typically found in industrial environments.

View Product