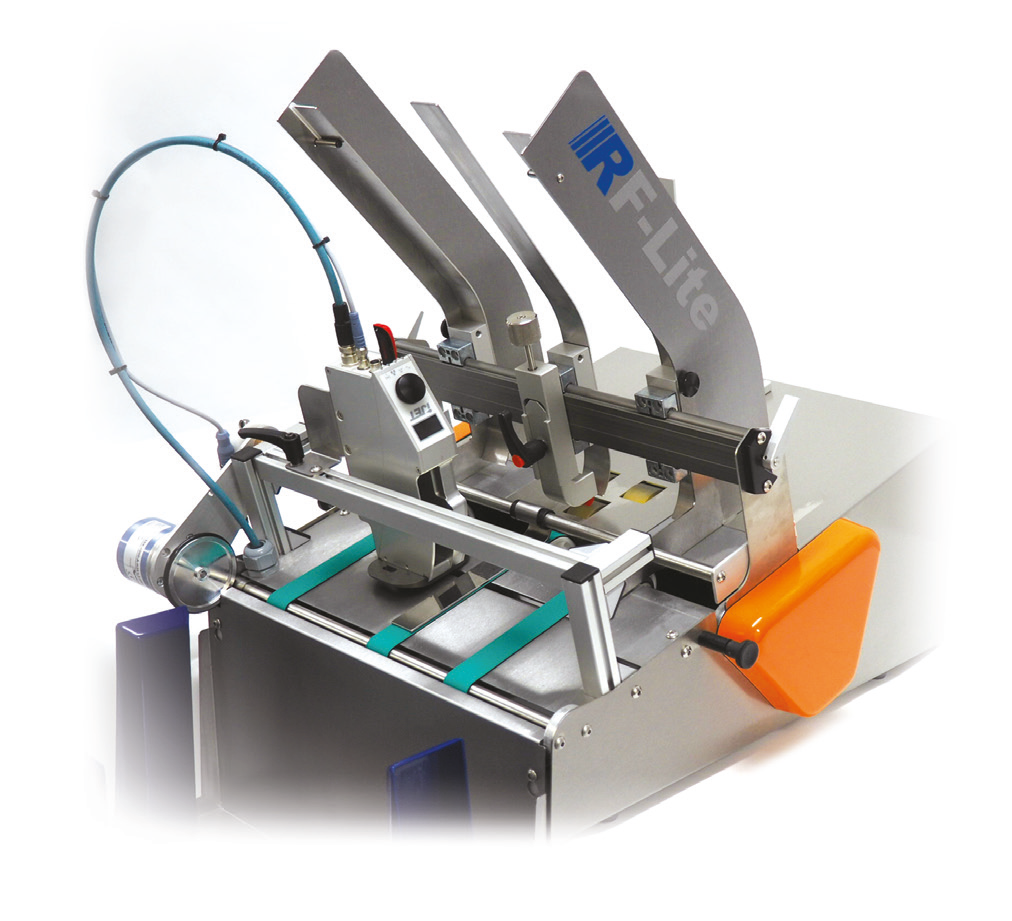

RF-Lite

Low-cost offline coding system; ideal for companies looking to automate their date marking process for the first time.

The RF-Lite is a simple, low-cost offline coding system; ideal for companies looking to automate their date marking process for the first time. It also suits larger operators who are looking to install dedicated marking systems on multiple production lines.

RIGHT CODE

Fitted with clean, thermal inkjet technology, the RF-Lite is ideal for printing

clear, concise date and batch codes onto sleeves and cartons.

RIGHT PLACE

The RF-Lite can consistently print codes onto all shapes and sizes of sleeve ranging

from 30 x 70mm to 300 x 200mm. It only takes a few seconds to swap between sizes.

RIGHT COST

With its comparatively low upfront cost, the RF-Lite is an ideal entry-level solution for companies wanting to automate their offline date coding.

“This compact unithas dramatically reduced

the time taken to codeour cartons.”

OTHER BENEFITS

• It’s easy to set up and adjust; no training needed.

• The RF-Lite’s tiny 500 x 500mm footprint means that it can be easily squeezed into tight spaces

• We offer a money-back guarantee if the system does not meet the customers needs and expectations*

• Under our one-year warranty we can replace a broken down RF-Lite unit within 24 hours*

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

RF-LiteGryphon 4100 – HC

The Gryphon family are successfully associated with their premium line of Datalogic ADC’s general purpose handheld data collection products. The Gryphon is ideally partnered with the Healthcare industry but has the flexibility to work across other industries. The Gryphon is extremely versatile and durable. The Gryphon is the ultimate solution for applications where mobility is […]

View ProductBlank Cards

Epson GP-C831 Printer

Our newly developed printhead protection system protects the ink head from dust to ensure reliable, continuous printing. In addition, Epson’s advanced DURA Brite pigment inks deliver outstanding stability and resistance to water, chemicals, fading and smudges. KEY FEATURES GHS label printer Ideal for large labels including large format drum and chemical labeling BS5609 certified Complies […]

View ProductHP (Hewlett-Packard)

Hewlett Packard is a printhead suitable for marking almost any product at high resolution.

Click on the Direct Sales Button, and contact us today to order your HP inkjet thermal inks.

View Product