Geset labelling machine – Geset 300

Geset 300 labelling machine for fast single side or all-round labelling

The basic concept of the Geset 300 labelling machine is based on two-sided labelling of moulded bottles without the use of run around text blocks. Adaptation to a specific product is done by simple adjustment of the machine components.

- Label dimensions: up to 250 mm high

- Clock frequency: up to 250 /min

The alignment and therefore highly accurate positioning of the labels is achieved through transport.

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

- Auto-switching Universal Power Supply for immediate adaptability anywhere in the world

- Compatible with all Direct Thermal and Thermal Transfer printers

- Electronic Speed Control will automatically synchronise winding speed to the speed of your printer

- Provides passive winding without skewing print or barcodes on your labels

- Rewind up to 61cm per second

- Easily handles labels up to 23cm wide

- Wind labels face in or face out

- Supports Tags up to 0.33 mm thick

- High Print Speed of 10 ips

- Large LCD Display

- Prints Brand Names and Logos

- Automated Print-Cut-Stack Function

- RFID Ready

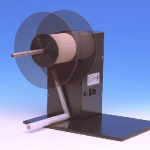

Electric Rewinder Models GLU-100 & Model GLR-100

XC Label Printer

The layout of the labels is created either using label software or through direct programming via a text editor on the PC. Label formats, fonts and graphic data, serial data and database contents are saved or imported on the CF memory card, USB flash drive or the internal IFFS printer memory. Only variable data is sent to the printer via keyboard or host computer before being printed out. Data from a barcode scanner or a balance can also be received by the printer.

View ProductSato – TG3 High Performance Printer

FEATURES

DS3608-DP/DS3678-DP 1D/2D

Unstoppable Performance for 1D/2D Direct Part Marks (DPM) and Bar Codes

As a member of the Zebra 3600 Ultra-Rugged Series of scanners, the practically indestructible 1D/2D DS3608-DP corded and DS3678-DP cordless scanner brings the dependable lightning-fast capture of virtually every direct part mark to aerospace, automotive and other manufacturing plants where end-to-end traceability of every product component is required.

View Product