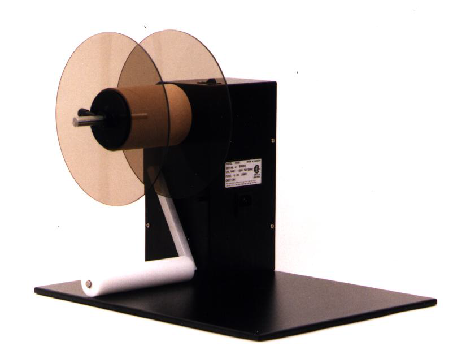

Electric Rewinder Model GLR-50

- Auto-switching Universal Power

- Supply for immediate adaptability anywhere in the world

- Compatible with all Direct Thermal and Thermal Transfer printers

- Electronic Speed Control will automatically synchronise winding speed to the speed of your printer

- Provides passive winding without skewing print or barcodes on your labels

- Rewind from 2.5cm to 25cm per second

- Easily handles labels from 2.5cm to 10cm wide

- Wind labels face in or face out

SPECIFICATIONS

Speed – 2.5 to 25.5 cm/sec

Roll Width – 2.5cm to 10.2 cm

Core Size – 7.6cm

Roll Diameter – 20.3 cm

Physical

Length – 25.5cm

Width – 25.5cm

Height – 21.5cm

Weight – 3.6kg

Electrical – 100 – 250 Volt 47 – 63Hz

Environment

Temperature – 5 to 40º

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

Electric Rewinder Model GLR-50Industrial Label Printers – High Performance for High Demands

Weber Marking’s industrial label printers are the perfect solution for automatic printing and labelling. From small systems with a broad range of applications to high-end demands with specialised needs, every industrial label printer is durable and can operate to maximum efficiency.

View ProductAlpha TIJ – Label dispenser Alpha with multifunctional inkjet-printer

The Alpha TIJ comprises a label dispenser of the proven and renowned Alpha series and a thermal inkjet printer.

View Product

Weber AP182 Pallet Labelling System

The Weber AP182 is the latest offering by Weber Packaging Solutions of the Pallet Labelling Systems range. It has the reliability and modularity of its predecessor the AL180 but with on board Intelligence and an enhanced User Interface. In the design of this system Weber has focused on reliability, connectivity, efficiency, and versatility. The AP182 System is designed to Label up to three sides of a Pallet simultaneously for specialist pallet identification applications.

View Product

Electronic Hand Held Label Applicator Model LD 70

Used directly from it’s own mains power supply or remotely from it’s rechargeable batteries, the LD70 can dispense and apply labels up to 65mm wide and there is no restriction on the maximum length.

View Product