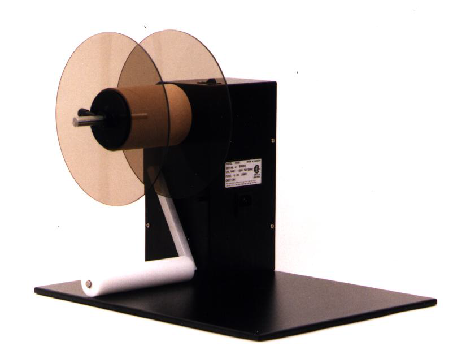

Electric Rewinder Model GLR-50

- Auto-switching Universal Power

- Supply for immediate adaptability anywhere in the world

- Compatible with all Direct Thermal and Thermal Transfer printers

- Electronic Speed Control will automatically synchronise winding speed to the speed of your printer

- Provides passive winding without skewing print or barcodes on your labels

- Rewind from 2.5cm to 25cm per second

- Easily handles labels from 2.5cm to 10cm wide

- Wind labels face in or face out

SPECIFICATIONS

Speed – 2.5 to 25.5 cm/sec

Roll Width – 2.5cm to 10.2 cm

Core Size – 7.6cm

Roll Diameter – 20.3 cm

Physical

Length – 25.5cm

Width – 25.5cm

Height – 21.5cm

Weight – 3.6kg

Electrical – 100 – 250 Volt 47 – 63Hz

Environment

Temperature – 5 to 40º

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

Electric Rewinder Model GLR-50Alpha TIJ – Label dispenser Alpha with multifunctional inkjet-printer

The Alpha TIJ comprises a label dispenser of the proven and renowned Alpha series and a thermal inkjet printer.

View Product

Weber LA 6000 Labelling System

High Performance Labelling System for Warehouse & Logistics

Modularity, High Performance necessary for Warehouse and Logistics System Solutions

View ProductGeset Labelling Machine

Fast, reliable, economical solutions to product labelling: Geset 100, 300 and 700 labelling machines are part of a modular system. Up to 50 modules are available for design solutions to customer demands. The Geset 100 is a labelling machine for small production series, designed to produce small volumes as accurately and flexibly as would a large plant. Its robust construction renders it ideal both for intermittent use of only a few minutes per day and for multiple shift operation.

View ProductMBA01 Manual Bottle Label Applicator

The NEW MBA01 is a manual applicator ideal for short and low volume applications and has been developed to apply labels to a wide range of cylindrical containers including Bottles, Jars, Cans, Tubs and Tubes.

View Product