EasyGo! ProductCheckPro

Summary

Manage your stock by checking the properties of your products and verifying they are correct. Alert, by incidents, the failures of the products checked. Send the incident report to the server to solve it or to have a movement report. Finally, print product related labels from your handheld device via cable, WiFi or Bluetooth.

Description

EasyGo!ProductCheckPro allows you to check any type of stock, with or without barcodes labels. The properties related to the product that will be showed are customizable for each customer.

The operator can easily identify the article in stock. Once identified, the operator can check all the information available for the item, such as price, batch number, and expiration date; or any property that has been customized.

Once the product has been identified, a label can be printed from the handheld device by cable, wifi or Bluetooth if available on the device. It’s possible to use several label formats, so the user will be able to choose the right label to print if more than one label format is available (for example, location label, price label…)

One label format is supplied with the solution as a sample (DPL) but it’s possible to supply additional formats to have the specific label required by the customer needs (size, printer model, information showed in the label, logo…).

EasyGo!ProductCheckPro needs a master file with all product codes in stock to be checked. It’s also recommended to provide an EAN master file and Incident master, to have a more complete and versatile application, but it’s not mandatory.

EasyGo!ProductCheckPro allows the operator to review any product, introducing an incident (for example, the price is incorrect), or a comment/suggestion (the description is too short). When the checking is finished, the incidents report will be ready to be uploaded, via cradle or WiFi, to the host.

If an incident master is provided, you can choose the description of the incident more appropriate and introduce any additional note. But if it is not provided, you can enter any comment or incidence note (free text).

Plus, if the host system is accessible from the device over WiFi network, an image of the article can also be displayed.

Languages

English

Spanish

![]()

![]()

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

- Auto-switching Universal Power

- Supply for immediate adaptability anywhere in the world

- Compatible with all Direct Thermal and Thermal Transfer printers

- Electronic Speed Control will automatically synchronise winding speed to the speed of your printer

- Provides passive winding without skewing print or barcodes on your labels

- Rewind from 2.5cm to 25cm per second

- Easily handles labels from 2.5cm to 10cm wide

- Wind labels face in or face out

Zebra ZD410 HC

The ZD410 healthcare model offers all of the features of the standard model plus disinfectant ready plastics and an IEC 60601-1 compliant power supply. Designed for hospital, clinic, laboratory and pharmacy applications, the direct thermal ZD410 helps to protect privacy by leaving no record on a ribbon of what has been printed. The optional 300 dpi print resolution is ideal for printing small labels. The ZD410 healthcare model is currently available for purchase only in North America and the European Union countries. It will be launched in other countries throughout 2016.

View ProductWeber Alpha HSM Label Applicator

The Alpha HSM (High Speed Modular) is our new modular compact Labelling System designed with versatility in mind.

View ProductNAUTIZ X3

POCKET SIZED POWERHOUSE

It’s not one thing that makes the Nautiz X3® a breakthrough in handheld technology – it’s the unbeatable combination of small size, big performance, extreme ruggedness and remarkable value. The Nautiz X3 is like nothing else on the market.

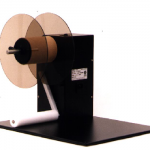

View ProductElectric Rewinder Model GLR-50