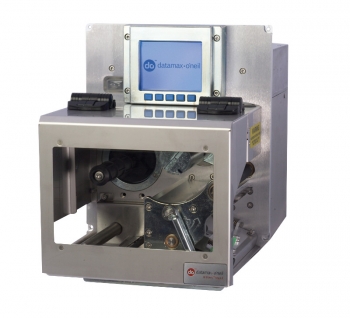

A – Class, Mark II Print Engine

When the demands of your high performance print and apply application require more features than existing print engines offer, it’s time to move up to the A-Class™ Mark II. The A-Class Mark II family of advanced print engines is designed for high-demand multi-shift applications requiring fast throughput and proven reliability. It includes a number of innovative design features such as stainless steel hardware components, a modular design for enhanced serviceability, coated side in/coated side out thermal transfer ribbon assembly, a full graphics display, intuitive menu navigation, and an optional remote display.

Designed for print and apply applicator integration, the A-Class Mark II utilizes the industry recognized Datamax-O’Neil firmware architecture with maximum connectivity options for industry standard communications interfaces. The A-Class Mark II with RFID option allows users to encode smart labels at the point of print, where most experts agree that encoding should take place to avoid any chance of mismatch between printed and encoded information. The RFID option currently accommodates EPCglobal Class 1/Gen 2 tags with either 64 or 96 bits of memory.

The A-Class Mark II is available in either 4” or 6” widths and is the only print engine to offer 203, 300, 400 and 600 dpi resolution in either right-hand or left-hand models.

Increased productivity – The A-Class increases productivity by providing fast throughput and proven reliability. The new design also allows for quick and easy replacement of the platen roller and printhead, cutting back on downtime and improving efficiency.

Integrates easily into existing solutions – The A-Class supports industry mounting standards for seamless integration into your system.

PL-Z (Zebra) and PL-I (Intermec) printer language emulation allows you to seamlessly integrate the A-Class into existing solutions without changing label formats.

Applications:

[one_third last=”no”]

Manufacturing

• Product Identification

• Shipping Labels

• Pallet Tracking Distribution

• Warehouse Logistics

• Cross Docking

• Shipping Labels

Food & Beverage

• Compliance

• Shipping Labels

• Product Identification[/one_third]

[one_third last=”yes”]

Pharmaceutical

• Compliance

• Product Identification

• Track & Trace

Health & Beauty

• Product Identification

• Shipping

• Track & Trace[/one_third]

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

Datamax-Oneill – AClassMII_final_rev0505101Zebra ZT400 Series Printers

The ZT400 Series builds on the field-proven reliability of the Z Series with advancements in print speed, print quality and connectivity options. Designed for ease of use, the ZT400 Series printers offer an intuitive icon-based LCD graphical user interface and easy supplies loading. And, they include standard USB, Serial, Ethernet and Bluetooth® capabilities. Expanded RFID capacities deliver greater tracking abilities, deeper visibility and enterprise insights.

View ProductZebra ZD410

The ZD410 is the smallest printer in its class, fitting easily in the most space-constrained desktop or shelf. Available with either 203 dpi or 300 dpi print resolution, the ZD410 is ideal for printing labels with a shelf life of less than one year. The ZD410 is currently available for purchase only in North America and the European Union countries. It will be launched in other countries throughout 2016.

View ProductPerformance Series

The Datamax-O’Neil p1120n Near Edge Performance Printer offers a unique near-edge printhead that allows full use of the label giving customers the ability to design and code barcodes that support detailed information. The flexible multimedia printing allows labels to be printed on synthetics, tags, self-adhesives and plastics. The near-edge printhead gives users the ability to integrate barcode printing across a wide variety of applications. The p1120n also offers auto-loading capabilities, a user-friendly touchscreen, and uses industry standard PCL printer language making it easy to integrate.

View ProductWeber LA 6000 Labelling System

High Performance Labelling System for Warehouse & Logistics

Modularity, High Performance necessary for Warehouse and Logistics System Solutions

View Product