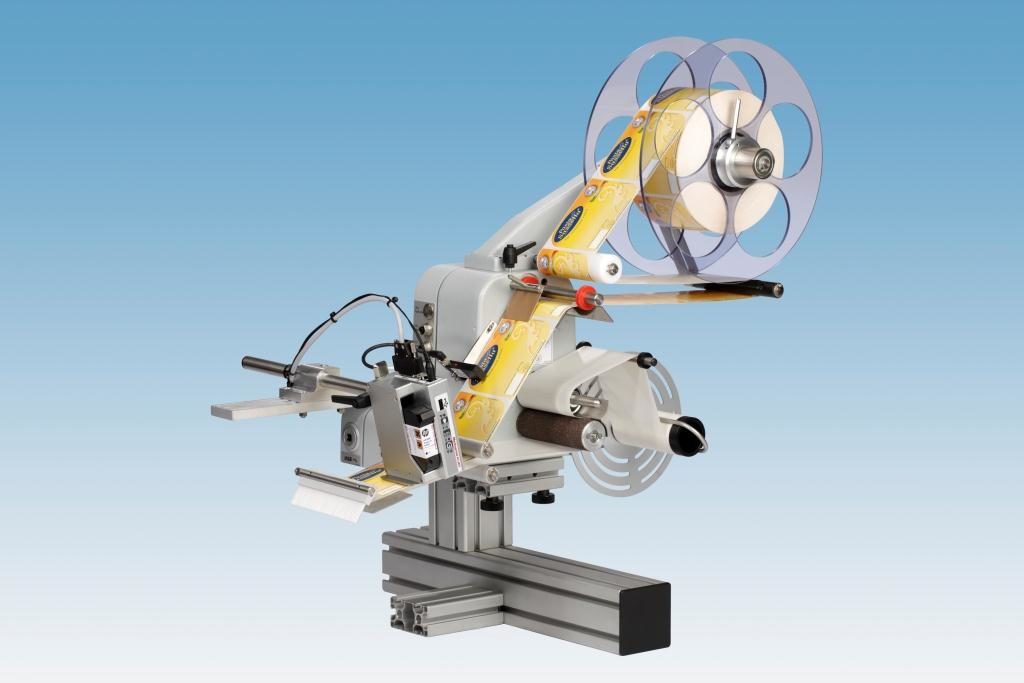

Alpha Compact X1 Jet

The Alpha Compact Inkjet combines the proven and renowned Alpha series labelling system with the compact Markoprint inkjet printer for a simple low cost Printing and Label Application Solution

The Alpha Compact Inkjet combines the proven and renowned Alpha series labelling system with the compact Markoprint Thermal inkjet printer. The cost-efficient Alpha Compact labeling system features a small footprint,  yet employs a highly-accurate wipe-on method of application to affix pressure-sensitive labels on a wide range of packages or products on your production line.

yet employs a highly-accurate wipe-on method of application to affix pressure-sensitive labels on a wide range of packages or products on your production line.

The Weber Markoprint X1/X2 Jet Thermal Ink Jet Coding Systems are high-resolution coders that provide reliable, cleanly-readable text and bar codes on your products. The Markoprint Coder is fitted to the Alpha Compact Labelling System by using an extended Peeler Bar fixture on the Alpha Compact Dispensing head giving you a modular solution that allows you to disable the Inkjet Coding System should you require Application Only of Pre-Printed Labels with the benefit of a simple Coding Solution for printing of Date Codes, 2D Codes etc. We see this product as an effective alternative to the larger more costly Printer and Apply Systems in the marketplace today.

The Markoprint X Jet systems are easy to operate. They use convenient HP/Lexmark ink jet cartridges that make it fast and easy to change ink formulations or add ink. If you need clean, high-resolution text, bar codes or graphics on your labels, then the X Jet systems are the solution. The ink dries almost immediately (depending on the formnulation) and is durable for most applications

Features and Benefits:

• Ideal solution for basic printing of, shelf life, barcodes, 2D codes, graphics and logos

• Easy to transmit data via USB, Ethernet, or directly from a PC

• Up to 3 000 serializations per minute and 600 dpi resolution, using low cost cartridge printing technology

• Up to 90 m per minute printing speed at 300 dpi resolution

• Integrated and automatic date functions with expiry calculator and serial numbers

If you are looking for a reliable, economical labeling system that is easy to set up and simple to maintain, then check out the Alpha Compact.

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

Alpha Compact X1JET leafletInk Guide 2015

Armor AWR470 Thermal Transfer Wax Ribbon

AWR®470 SolFree® is the only ribbon in the world to be coated without using solvents, including for the backcoating. SolFree® represents a saving of 365g of CO2 compared to the same ribbon (with average dimensions) produced with a traditional process for the backcoating. AWR®470 SolFree® is well known for its high coverage ability which is essential for printing the rough materials widely used in logistics.

View ProductPressure-Sensitive Bakery Labels

Great bakery labels need to visually enhance the product that they decorate as well as communicate required information like nutrition facts, ingredients and expiration dates. A good label design will include colorful images and use materials like clear film or metallic foils to showcase the product and draw customers near.

View ProductPrint, Code & Apply Flag Tag

The label applicator LA 5200 RFID is a true all-rounder, providing an all-in-one solution. The “Print, Code & Apply Flag Tag” process involves the automatic writing, printing and application of tags.

View ProductSolicom ClockInOut

Summary

Solicom ClockInOut is an easy to use application, with just a single screen showing the current time and after scanning a badge, a welcome or goodbye message is shown for the person just scanned. Badges that are allowed for entrance can be put in a lookup table. All badges scanned are saved in a report table. Via a supervisor menu, activated by a configurable special badge number, the download and upload of both tables can be controlled.

View Product