Markoprint Integra PP 108

The Markoprint Integra PP108 is the first inkjet printer with SEIKO printing technology and a circulating ink system. It features a POZIFLOW circulating ink system which prevents the accumulation of air in the nozzles and ensures a permanent, clean print image without missing print due to blocked nozzles. The system’s ink tank can be installed above, below, or at the same height as the print head without any problems. The new SEIKO printhead has a print height of 108 mm and achieves a remarkable speed of up to 150 meters per minute with a high resolution of 360 dpi.

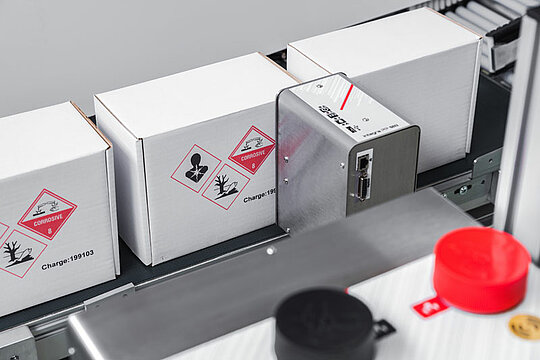

Suited to Dual Colour Printing Applications such as Hazard Labelling, Dual Colour overprinting and Direct Printing Applications to corrugate, and web printing applications, the PP108 is the latest high end, economical Inkjet System using the latest Drop on Demand Printing Technology.

The Markoprint PP108 utilises state-of-the-art Seiko Printhead technology producing two colour printing up to 108mm high on porous substrates.

-

-

- High quality print up to 360 dpi

-

- High print speed of up to 150m/min (at 360 dpi)

-

- Maintenance Free Inkjet System (no servicing required)

-

- Up to 108mm print height without offset

-

- Prints grayscale or Dual Colour

-

- Easy start-up and airing of the ink system

-

- Two 700ml ink tanks for two colour printing over an extended time

-

- Ideal for Integration into an existing Packaging Machine or Web Printing Applications

-

- Pigmented MOF oil ink (mineral oil-free): ideal for printing on absorbent surfaces in the food industry

-

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

Inkjet Coding Systems BrochureBlank labels

Purchasing Weber Self Adhesive Labels and Tags provides you with access to a large selection of quality, pre-tested, stock and custom supplies manufactured by a Global Industry Expert

View ProductZXP Series 7

HIGH PERFORMANCE CARD PRINTERS

Using the latest in Zebra card-printing technology, the ZXP Series 7 provides high-quality card printing. The ZXP Series 7 printer has an innovative design. It automatically adjusts to the thickness of the card, and ribbon loading is easy.With color coded guides and a clear LCD control panel, it’s simple for anyone to use.

View ProductZebra DS4308-HC HEALTHCARE SCANNER

In the mission-critical world of healthcare, caregivers need to be able to accurately capture virtually any barcode, on any medium, in any condition — with first-time every time predictability. And with the DS4308-HC on your workstations-on-wheels and other carts, they can. The DS4308-HC does it all — 1-D or 2-D, electronic or printed on paper labels, tiny dense codes on the curved surface of a vial, codes printed on reflective surfaces like IV bags, codes under shrink wrap on doses of medication — and even smudged, scratched or poorly printed barcodes. The result? The priceless peace of mind that the right patient received the right medication and the right test results, every time.

View ProductX4Jet Plus

With the new high performance Markoprint X4JET print controller, different inkjet printing technologies can be controlled either simultaneously or alternately. The intuitive input unit of the new high performance Markoprint X4JET plus print controller is a boost to operator convenience. All system parameters can be entered easily and quickly, to be stored and called up later.

View Product