When designing variable-printed barcode labels, there are many points to consider, which result from the application: Which texts, graphics, barcodes must be included? Which font sizes should be selected? Which parts should be pre-printed, which should be supplemented with the printer variably?

Printing conditions are also important. How wide is the label to allow the printer to print? Is it necessary to rotate a label that is too wide by 90 ° so that it comes out of the printer with the narrow side? Or can a label printer be used which is wide enough for application without rotation? Do you match the ribbon and the label material and does the print meet the necessary requirements in terms of legibility and legibility?

From these considerations, a specific position and orientation is obtained for the possibly contained barcode. It comes either from the printer, transversely to the printing direction , or is printed like a “fence” on the label – or the barcode is printed in the printing direction and appears as a “ladder” on the label.

The alignment directly affects the legibility of the barcode, as we shall see below.

Print bar code

A thermal transfer printer has a fixed print head that covers the entire width of the label. It has a large number of tiny heating elements sitting closely next to each other, in an extreme case more than 23 pieces per millimeter.

The heating elements are switched on and off electronically. When printing, the label material is advanced by the printer. In the course of pre-drying, either the label material is stained by the heat in the correct place (thermally direct) or a coated ribbon , which is guided in parallel with the label, heats up spot-wise, the color particles thereon melt and transfer to the label material (thermal transfer). The typeface appears on the label. It is therefore ultimately composed of many small points – often also called “Dot”.

The following video shows the printing and removal of the finished label from the printer.

Especially with a barcode, the same print quality is an important goal. No stroke may be missing or incorrectly printed so that it can be read correctly by the reading devices. Therefore, you must clean the print head regularly, so that no deposits are formed there.

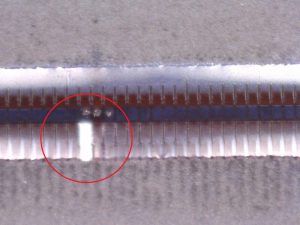

But despite all care: in the end, the best print head is also worn out and a single “dot” is missing. Or a contamination ensures that the one or the other dot does not have the necessary effect before the next cleaning.

In certain circumstances, such a failure does not occur immediately. To be sure, you can, of course, position a barcode sanner behind the printer that checks each code for readability. For complex applications possible, but in simple applications this is often out of the question.

Trick: Thick line

Here is a little trick: If you place a thicker closed line above the barcode into the label, then you can see on this line also with the naked eye and without a scanner immediately, whether the print bar on the entire width of the barcode still working properly.

If possible, you can rotate the barcode (and, of course, all the rest of the label content!) In the layout by 90 °. Then the eventual defective dot passes through the entire printed image of the code and leaps into the eye.

Be careful when turning the bar code

The rotation, however, still has a technical consequence, which should not be omitted: the turning on and off of the dots takes place at very high printing speeds in a very fast sequence. Electronically, the speed is not a problem, but the heating element naturally has a certain inertia. Even after shutting down, it is still a little warm. In the case of very high printing speeds, it might happen that the lines have a somewhat frayed effect. Especially in the case of a bar code, this could lead to problems with regard to readability, since a very high edge sharpness is necessary for the lines and gaps. It is therefore necessary to check whether a rotation of the barcode is at all possible with the material combination used and with the necessary printing speeds.

So, enough technique for today. To the loosening again a review of the barcode conspiracy, which went through the press several years ago. Bars above, under or through the barcode could have quite different reasons …. But read and see for yourself .

Image source: BluhmWeber Group