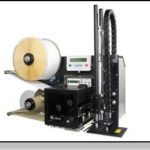

Weber 114 One-Sided/Two-Sided Labelling System

The brand-new Weber 114 system provides a simple, cost-effective solution to low volume labelling for applying labels to one or two sides of a straight-walled product or package. The Model 114 can be added to in-place production lines or operated manually as a stand-alone applicator.

The Weber 114 is easy to use and can be set-up quickly. During application, labels are peeled away from the liner and securely attached to products using the wipe-on label applicators.

The unit boasts robust steel construction making it perfect for lower-volume, intermittent labelling projects or multiple-shift larger-scale operations. This is a very reliable wipe-on application system that is built to last.

-

-

- Applies label up to 6″ high x 12″ long

-

-

-

- Handles up to 45 products/minute

-

-

-

- Placement accuracy of 0.03″

-

Products are delivered to the Weber 114’s built-in Alpha Compact applicator heads via a 7.75″-wide, 45″-long belt conveyor, which permits product transfers at both the entry and discharge ends. The unit is capable of a superb placement accuracy of 0.03″.

Each version of the Alpha Compact features rugged die-cast aluminium construction, single-key calibration, automatic recognition of missing labels, in-production speed adjustment, and more.

The controller for the Weber 114 (seen at right) features a display HMI that replaces the operator’s panel with an LCD display that provides full access to all adjustment parameters.

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

- Depth – No Maximum

- Max. Reel Diameter – Max. 225mm

- Core Size – Min. 25mm Ideal 76mm

Electric Semi-Automatic Label Dispensers

These machines can dispense up to a maximum web width of 152mm butt cut or die cut and adjustments for different size labels are made easily

and without the need for tools.

View Product

Weber Legi-Air 4050E – Precision Labelling System

Based on a modular construction the Weber 4050E is capable of numerous methods to print and apply a label. The design comprises a feeder module, a printing module, label winder and unwinder with numerous applicator types. The standard Tamp-Blow system has a quick-change system for changing the tamp pad which significantly reduces the changeover time to other label formats.

View ProductIndustrial Label Printers – High Performance for High Demands

Weber Marking’s industrial label printers are the perfect solution for automatic printing and labelling. From small systems with a broad range of applications to high-end demands with specialised needs, every industrial label printer is durable and can operate to maximum efficiency.

View ProductLegi-Air 5300 Tyre Label Printer-Applicator

According to an EU regulation all new tires produced in or after January 2012 and placed on the market within the EU must bear a standardized EU sticker, such as those already seen on washing machines and refrigerators. The new label must contain precise details with seven grades (A-G) of fuel efficiency, wet grip, and exterior noise when in motion (in dB), respectively.

View Product