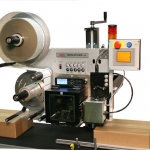

Weber Alpha HSM Label Applicator

The Alpha HSM (High Speed Modular) is our new modular compact Labelling System designed with versatility in mind.

No two packaging lines are the same these days, with many companies demanding more flexibility for new automated labeling equipment to fit their existing production lines. The Weber Alpha HSM is the solution – a compact modular high speed servo driven new label applicator that can be configured to fit just about any packaging line.

Our new label applicator Alpha HSM is a high-performance and universally adaptable applicator system in a new design, with even better efficiency, higher cycle rates and even simpler operation than its tried and tested predecessor the Alpha Compact. The modular concept design adapts flexibly to confined production spaces and easy to install into existing packaging lines and systems.

The modular Labelling System consists of a drive module, a label detection module, a dispensing module, an unwinder module, a rewinder module and an adapter module. These can be assembled according to a customers specification using our configurator to create the perfect label applicator for their product line. More than 70 different configurations are available for a multitude of labelling applications. This makes the Alpha HSM the most versatile solution in our labelling systems portfolio

With the packaging industry asking for higher labeling speeds and more flexibility, the Alpha HSM high speed labelling systems can be configured in a variety of models that can handle multiple speeds and label sizes.

Weber engineered the modular Alpha HSM so that it can be ordered in ten different sizes to fit just about any labeling application. Available in right- or left-hand versions, the Alpha HSM can be built with 135, 200, 250 and 320 mm label widths.

IP65

The Alpha HSM is IP65 certified and is constructed of durable aluminum with high rigidity for all working label widths, including wash down areas.

Interfacing

All the systems feature multiple interfaces allowing connections for HMI display, product detector, rotary encoder, I/O signal, Ethernet network, and an aux in and aux out for sensor attachment. Three different user interfaces are available including OLED display, external PLC module or a web-based browser control.

Modular Options

The standard mechanical label unwinder and rewinder can be upgraded to a motorized servo-controlled system for higher labeling throughput speeds. Label application modules for the HSM include a fixed peeler plate, a swiveling peeler plate, a pneumatic peeler plate, and adjustable peeler plate or a pneumatic applicator. Label sensors can handle standard and transparent labels.

Summary Features

- The Alpha HSM can apply any type of adhesive label to virtually any type of product or package.

- Currently in use in a number of industries, including pharmaceutical, cosmetics, logistics, food and beverages, including automotive and chemical.

- System can be mounted in a number of orientations and configurations.

- Easy to integrate into any packaging line or System Solution

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

You must be logged in to access these documents. Register for an account.Weber AP182 Pallet Labelling System

The Weber AP182 is the latest offering by Weber Packaging Solutions of the Pallet Labelling Systems range. It has the reliability and modularity of its predecessor the AL180 but with on board Intelligence and an enhanced User Interface. In the design of this system Weber has focused on reliability, connectivity, efficiency, and versatility. The AP182 System is designed to Label up to three sides of a Pallet simultaneously for specialist pallet identification applications.

View Product

Sustainable Labels

We offer a number of sustainable label products, including renewable films and papers, 100 percent post-consumer waste papers, dis-solvable and reputable papers, soy-based inks, and more. We believe that what is good for business can be better for the environment. We do not believe that being green has to cost more; no packaging professional should accept that. Here at Weber, we pledge to strive to develop products and process that improve our environment and our bottom line.

Geset 141 Semi Automatic Label Dispenser

The Geset 141 semi-automatic all-round labelling system is used for labelling small tins, bottles, jars etc. This solution was developed especially for companies requiring flexible labelling of small batches. Classical applications include the pharmaceutical and cosmetics industry and the food and beverage sector.

View Product

Model 5300 Series Air-Blow Label Printer-Applicator

This Weber exclusive provides high-resolution printing and high-speed operation combined with the dependable air-blow method of label application.

•Choose from a wide range of 203, 300 and 600 dpi print engines

•Capable of handling print speeds up to 16 ips

•Numerous I/O’s ease interfacing with external devices

•Monitor operation via a web browser

•Available with RFID capability